2021 China New Design Biodegradable Plastic Bags Raw Material - Biodegradable 3D Printing Modified Materials – Siko

2021 China New Design Biodegradable Plastic Bags Raw Material - Biodegradable 3D Printing Modified Materials – Siko Detail:

Several technologies such as annealing, adding nucleating agents, forming composites with fibers or nano-particles, chain extending and introducing crosslink structures have been used to enhance the mechanical properties of PLA polymers. Polylactic acid can be processed like most thermoplastics into fiber (for example, using conventional melt spinning processes) and film. PLA has similar mechanical propertiesto PETE polymer, but has a significantly lower maximum continuous use temperature. With high surface energy, PLA has easy printability which makes it widely used in 3-D printing. The tensile strength for 3-D printed PLA was previously determined.

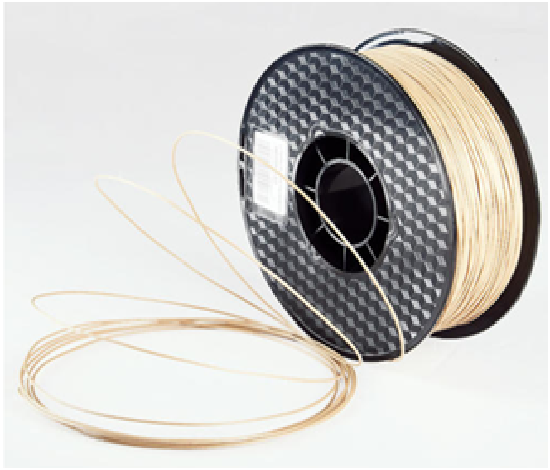

PLA is used as a feedstock material in desktop fused filament fabrication 3D printers . PLA-printed solids can be encased in plaster-like moulding materials, then burned out in a furnace, so that the resulting void can be filled with molten metal. This is known as “lost PLA casting”, a type of investment casting.

SPLA-3D Features

Stable molding

Smooth printing

Excellent mechanical properties

SPLA-3D Main Application Field

High toughness, high strength 3D printing modified material,

Low-cost, high-strength 3D printing modified materials

SPLA-3D Grades And Description

| Grade | Description |

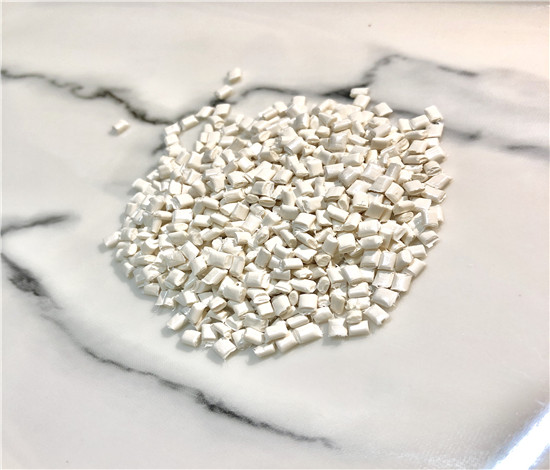

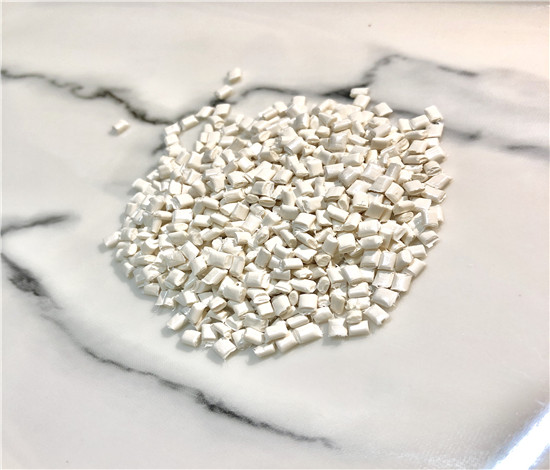

| SPLA-3D101 | High-performance PLA. PLA accounts for more than 90%. Good printing effect andhigh intensity. The advantages are stable forming, smooth printing and excellentmechanical properties. |

| SPLA-3DC102 | PLA accounts for 50-70% and is mainly filled and toughened. The advantages arestable forming, smooth printing andexcellent mechanical properties. |

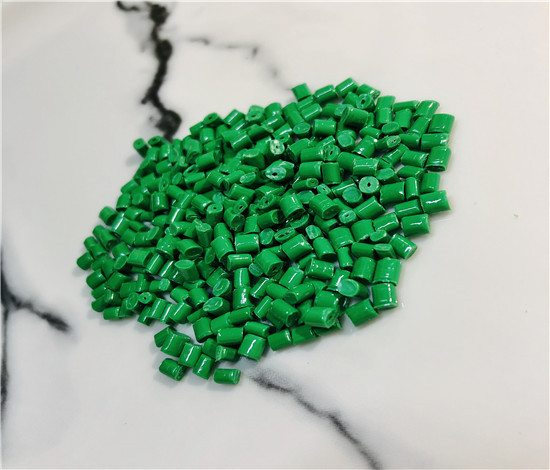

Product detail pictures:

Related Product Guide:

We thinks what prospects think, the urgency of urgency to act from the interests of a client position of theory, allowing for greater high-quality, reduced processing costs, rates are much more reasonable, won the new and previous consumers the support and affirmation for 2021 China New Design Biodegradable Plastic Bags Raw Material - Biodegradable 3D Printing Modified Materials – Siko , The product will supply to all over the world, such as: Plymouth, Moldova, Philippines, We've got constructed strong and long co-operation relationship with an enormous quantity of companies within this business overseas. Immediate and specialist after-sale service supplied by our consultant group has happy our buyers. In depth Info and parameters from the merchandise will probably be sent to you for any thorough acknowledge. Free samples may be delivered and company check out to our corporation. n Portugal for negotiation is constantly welcome. Hope to get inquiries type you and construct a long-term co-operation partnership.

The product manager is a very hot and professional person, we have a pleasant conversation, and finally we reached a consensus agreement.