2021 High quality Eco Friendly Plastic Bag - High performance PPS+PPO/GF alloy for auto parts – Siko

2021 High quality Eco Friendly Plastic Bag - High performance PPS+PPO/GF alloy for auto parts – Siko Detail:

PPS+PPO/GF Features

Excellent heat resistance, continuous use temperature up to 220-240 ° C, glass fiber reinforced heat distortion temperature above 260 ° C

Good flame retardant and can be UL94-V0 and 5-VA (no dripping) without adding any flame retardant additives.

Excellent chemical resistance, only second to PTFE, almost insoluble in any organic solvent

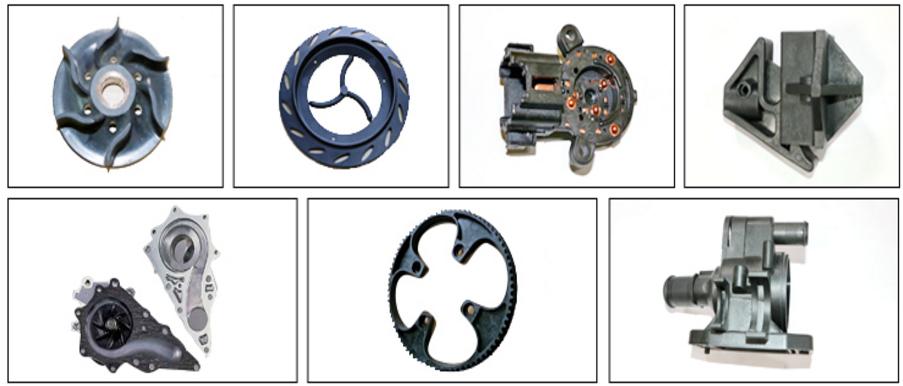

PPS resin is highly reinforced by glass fiber or carbon fiber and has high mechanical strength, rigidity and creep resistance. It can replace part of metal as structural material.

The resin has excellent dimensional stability.

Extremly small molding shrinkage rate, and low water absorption rate. It can be used under high temperature or high humidity conditions.

Good fluidity. It can be injection molded into complex and thin-walled parts.

PPS+PPO/GF Main Application Field

Widely used in machinery, instrumentation, automotive parts, electrical and electronic, railway, home appliances, communications, textile machinery, sports and leisure products, oil pipes, fuel tanks and some precision engineering products.

|

Field |

Application Cases |

| Household Appliances | Hairpin and its heat insulation piece, electric razor blade head, air blower nozzle, meat grinder cutter head, CD player laser head structural parts |

| Electronics | Connectors, electrical accessories, relays, copier gears, card slots, etc |

| Industrial parts and consumer products | Dashboard, battery pack, switchboard, radiator grille, steering column housing, control box, anti-frost device trim, fuse box, relay housing assembly, headlight reflector. |

SIKO PPS+PPO/GF Grades And Description

|

SIKO Grade No. |

Filler(%) |

FR(UL-94) |

Description |

|

SPE4090G10/G20/G30 |

10%-30% |

HB |

PPO+10%,20%,30% GF, good rigidity and chemical resistance. |

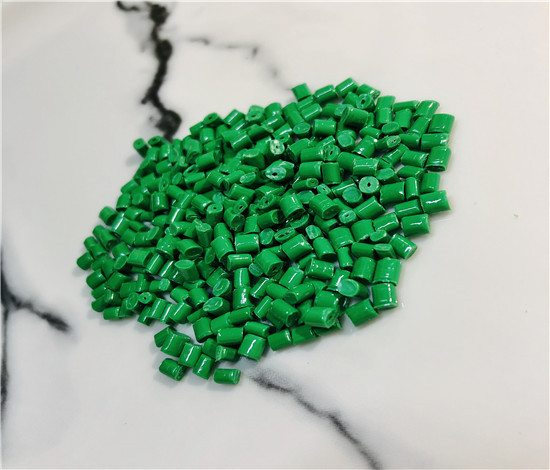

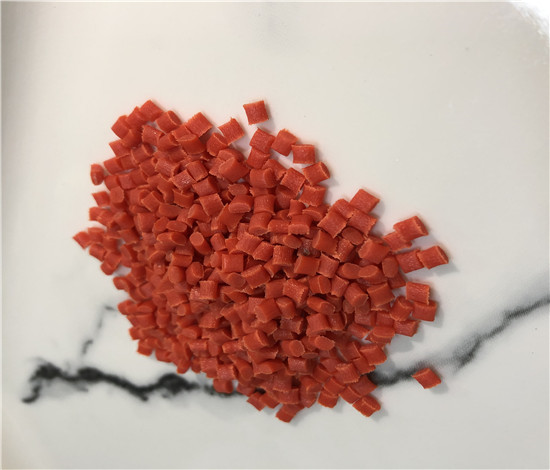

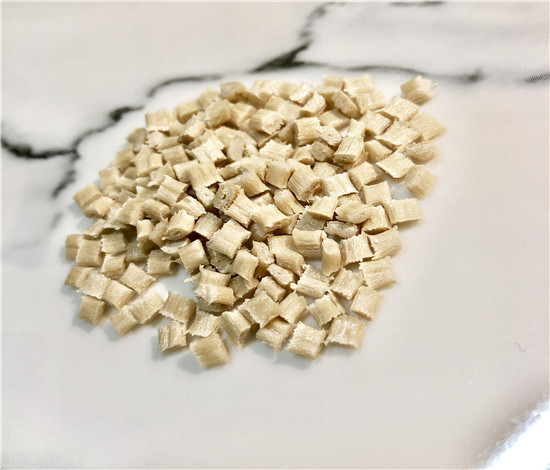

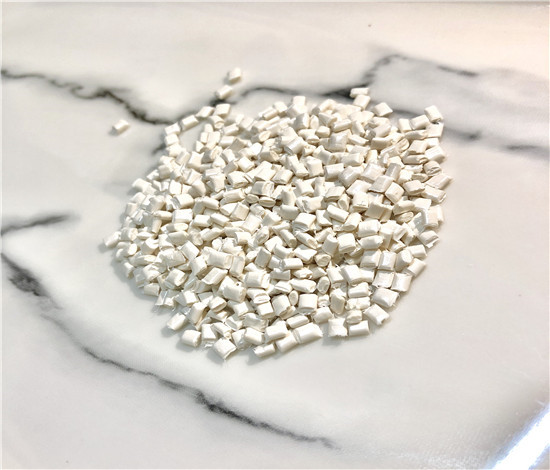

Product detail pictures:

Related Product Guide:

As for aggressive costs, we believe that you will be searching far and wide for anything that can beat us. We can state with absolute certainty that for such high-quality at such rates we have been the lowest around for 2021 High quality Eco Friendly Plastic Bag - High performance PPS+PPO/GF alloy for auto parts – Siko , The product will supply to all over the world, such as: Auckland, Grenada, Madagascar, Providing Quality Items, Excellent Service, Competitive Prices and Prompt Delivery. Our products and solutions are selling well both in domestic and foreign markets. Our company is trying to be one important suppliers in China.

Company director has very rich management experience and strict attitude, sales staff are warm and cheerful, technical staff are professional and responsible,so we have no worry about product,a nice manufacturer.