2021 wholesale price Pla Compostable Plastic - Material plastic PPS+PA66/GF for automotive industry – Siko

2021 wholesale price Pla Compostable Plastic - Material plastic PPS+PA66/GF for automotive industry – Siko Detail:

PPS+PA66/GF Features

It has excellent mechanical properties, high strength, high toughness, but high water absorption, so the dimensional stability is poor.

The density is only 1.5 ~ 1.9g/ cc, but aluminum alloy is around 2.7 g/cc, steel is around 7.8g/cc. It can greatly reduce weight, excellent performance on metal replacement.

By filling the solid lubrication material, making the PPS composite material with good resistance to bite, low friction coefficient, wear resistance, self-lubrication, silencing shock absorption.

The molding shrinkage rate is very small; Low water absorption rate, small linear thermal expansion coefficient; Good dimensional stability will still show under high temperature or high humidity, and the molding shrinkage rate is 0.2 ~ 0.5%.

PPS+PA66/GF Main Application Field

| Field | Application Cases |

| Automotive | Cross connector, brake piston, brake sensor, lamp bracket, etc |

| Household Appliances | Hairpin and its heat insulation piece, electric razor blade head, air blower nozzle, meat grinder cutter head, CD player laser head structural parts |

| Machinery | Water pump, oil pump accessories, impeller, bearing, gear, etc |

| Electronics | Connectors, electrical accessories, relays, copier gears, card slots, etc |

SIKO PPS+PA66/GF Grades And Description

| SIKO Grade No. | Filler(%) | FR(UL-94) | Description |

| SPS98G30F/G40F | 30%,40% | V0 | PPS/PA alloy, with 30%/40% GF reinforced |

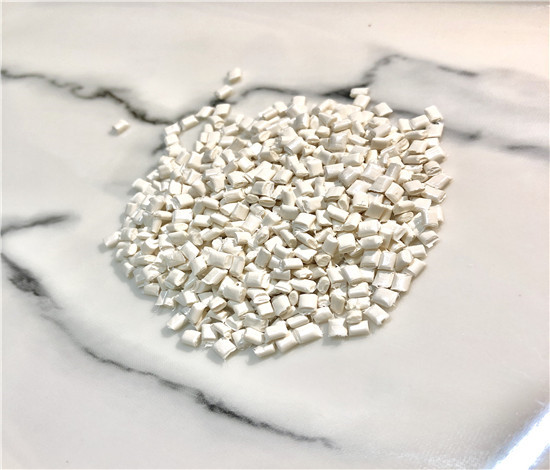

Product detail pictures:

Related Product Guide:

We now have a specialist, efficiency workforce to deliver excellent service for our purchaser. We always follow the tenet of customer-oriented, details-focused for 2021 wholesale price Pla Compostable Plastic - Material plastic PPS+PA66/GF for automotive industry – Siko , The product will supply to all over the world, such as: belarus, Pretoria, Wellington, If any product meed your demand, remember to feel free to contact us. We're sure your any inquiry or requirement will get prompt attention, high-quality merchandise, preferential prices and cheap freight. Sincerely welcome friends all over the world to call or come to visit, to discuss cooperation for a better future!

This is a reputable company, they have a high level of business management, good quality product and service, every cooperation is assured and delighted!