Cheap price Pbt Gf30 V0 - Material plastic Thermoplastics TPE&TPU for electrical and electronic – Siko

Cheap price Pbt Gf30 V0 - Material plastic Thermoplastics TPE&TPU for electrical and electronic – Siko Detail:

TPE and TPU compounds offer excellent color ability, clarity, flexibility, and elasticity. TPUs are a subset of TPEs – both are block copolymers, made of different building blocks. These material classes can be used for extrusion, injection molding applications and other plastics molding processes. Both material classes will not lose their structural integrity when reprocessed, allowing for the cost-saving reuse of production waste.

Thermoplastic elastomeric (TPE) and thermoplastic polyurethane (TPU), which is a subset of TPE, offer great versatility as alternatives to natural rubber latex, silicone and more compounds for extrusion and injection molding applications. Depending on the demands of your product and industry TPE or TPU could be the compound choice you need.

TPE&TPU Features

Weather resistance and low temperature characteristics

Good weather resistance and low temperature

Good oil and chemical resistance

Soft and elastic touch

Skid resistance and tightness

Easy to process without special equipment

Shock absorption and sound insulation

With medical food certification

It can be used to strengthen and toughen plastics

TPE&TPU Main Application Field

Widely used in automotive parts, electrical and electronic, railway, communications, textile machinery, sports and leisure products, oil pipes, footwear and some precision engineering products.

| Field | Application Cases |

| Auto Parts | Ball coupling; Dust cover.Pedal brake; Door lock firing pin; bushing |

| electric wire | Electric communication cable; Computer wiring; Automobile wiring; Exploration cable, |

| Footwear | Softball shoes, baseball shoes, golf shoes, football shoes soles and front shoes |

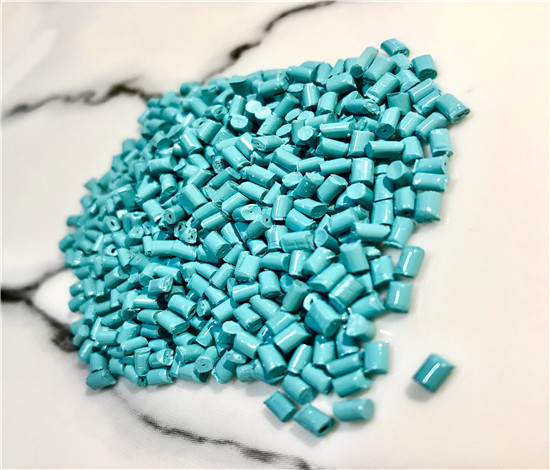

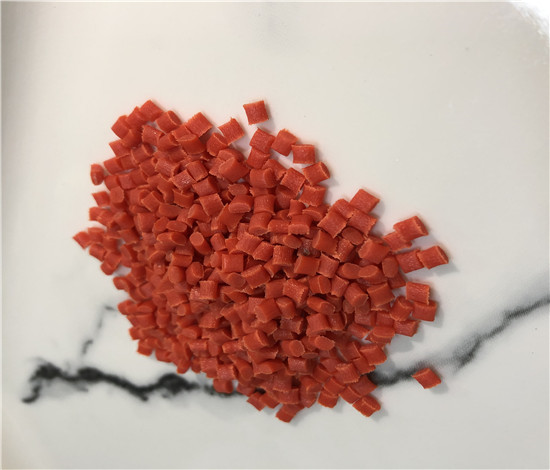

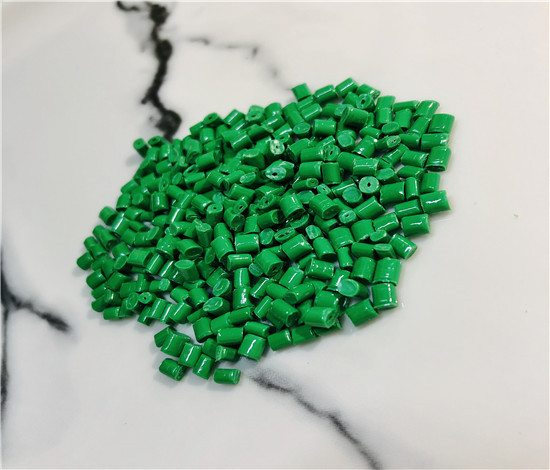

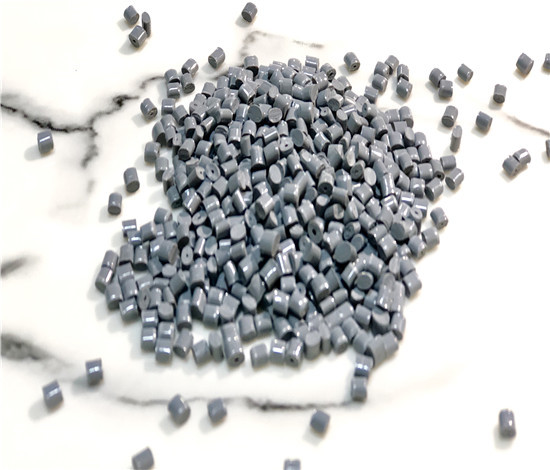

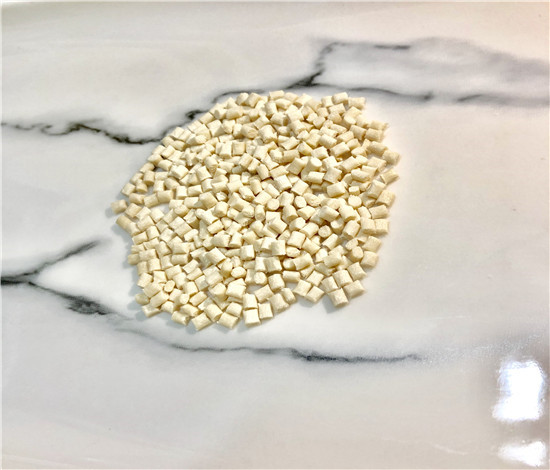

Product detail pictures:

Related Product Guide:

We offer fantastic strength in high quality and enhancement,merchandising,income and marketing and procedure for Cheap price Pbt Gf30 V0 - Material plastic Thermoplastics TPE&TPU for electrical and electronic – Siko , The product will supply to all over the world, such as: United Arab emirates, Angola, Bahrain, We adhere to the honest, efficient, practical win-win running mission and people-oriented business philosophy. Excellent quality, reasonable price and customer satisfaction are always pursued! If you are interested in our products, just try to contact us for more details!

The goods are very perfect and the company sales manager is warmful, we will come to this company to purchase next time.