Cheap PriceList for Pet V0 - PI (Polyimide) Powder, Rod, Sheet, CNC Design Products – Siko

Cheap PriceList for Pet V0 - PI (Polyimide) Powder, Rod, Sheet, CNC Design Products – Siko Detail:

Thermosetting polyamides are known for thermal stability, good chemical resistance, excellent mechanical properties, and characteristic orange/yellow color. Polyamides compounded with graphite or glass fiber reinforcements have flexural strengths of up to 340 MPa (49,000 psi) and flexural moduli of 21,000 MPa (3,000,000 psi). Thermoses polymer matrix polyamides exhibit very low creep and high tensile strength. These properties are maintained during continuous use to temperatures of up to 232 °C (450 °F) and for short excursions, as high as 704 °C (1,299 °F).[11] Molded polyimide parts and laminates have very good heat resistance. Normal operating temperatures for such parts and laminates range from cryogenic to those exceeding 260 °C (500 °F). Polyamides are also inherently resistant to flame combustion and do not usually need to be mixed with flame retardants. Most carry a UL rating of VTM-0. Polyimide laminates have a flexural strength half life at 249 °C (480 °F) of 400 hours.

Typical polyimide parts are not affected by commonly used solvents and oils – including hydrocarbons, esters, ethers, alcohols and ferns. They also resist weak acids but are not recommended for use in environments that contain alkalis or inorganic acids. Some polyamides, such as CP1 and CORIN XLS, are solvent-soluble and exhibit high optical clarity. The solubility properties lend them towards spray and low temperature cure applications.

PI Features

PI is its own flame retardant polymer, which does not burn at high temperature

Mechanical properties low sensitivity to temperature

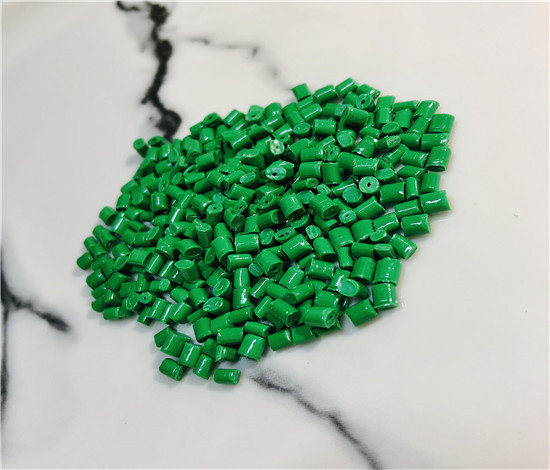

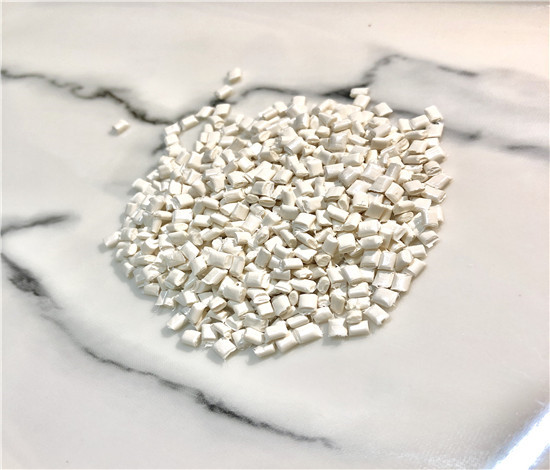

The material has excellent coloring ability, can achieve various requirements of color matching

Excellent thermal performance: High temperature and low temperature resistance

Outstanding electrical performance: High electric insulation

PI Main Application Field

Widely used in machinery, instrumentation, automotive parts, electrical and electronic, railway, home appliances, communications, textile machinery, sports and leisure products, oil pipes, fuel tanks and some precision engineering products.

Polyimide materials are lightweight, flexible, resistant to heat and chemicals. Therefore, they are used in the electronics industry for flexible cables and as an insulating film on magnet wire. For example, in a laptop computer, the cable that connects the main logic board to the display (which must flex every time the laptop is opened or closed) is often a polyimide base with copper conductors. Examples of polyimide films include Apical, Kapton, UPILEX, VTEC PI, Norton TH and Kaptrex.

An additional use of polyimide resin is as an insulating and passivation layer in the manufacture of Integrated circuits and MEMS chips. The polyimide layers have good mechanical elongation and tensile strength, which also helps the adhesion between the polyimide layers or between polyimide layer and deposited metal layer.

| Field | Application Cases |

| Industry Part | High temperature self-lubricating bearing, compressor piston ring, seal ring |

| Electrical accessories | Radiators, cooling fan, door handle, fuel tank cap, air intake grille, water tank cover, lamp holder |

SPLA-3D Grades And Description

| Grade | Description |

| SPLA-3D101 | High-performance PLA. PLA accounts for more than 90%. Good printing effect andhigh intensity. The advantages are stable forming, smooth printing and excellentmechanical properties. |

| SPLA-3DC102 | PLA accounts for 50-70% and is mainly filled and toughened. The advantages arestable forming, smooth printing andexcellent mechanical properties. |

Product detail pictures:

Related Product Guide:

We always continually offer you by far the most conscientious customer service, and the widest variety of designs and styles with finest materials. These attempts include the availability of customized designs with speed and dispatch for Cheap PriceList for Pet V0 - PI (Polyimide) Powder, Rod, Sheet, CNC Design Products – Siko , The product will supply to all over the world, such as: Bulgaria, New York, Myanmar, In order to meet our market demands, we have paied more attention to the quality of our products and services. Now we can meet customers' special requirements for special designs. We persistently develop our enterprise spirit "quality lives the enterprise, credit assures cooperation and keep the motto in our minds: customers first.

The company leader recept us warmly, through a meticulous and thorough discussion, we signed a purchase order. Hope to cooperate smoothly