China Cheap price Polyamide Resin - Material plastic PEEK-UNFILLED GF, CF for power tools – Siko

China Cheap price Polyamide Resin - Material plastic PEEK-UNFILLED GF, CF for power tools – Siko Detail:

PEEK is a semi crystalline thermoplastic with excellent mechanical and chemical resistance properties that are retained to high temperatures. The processing conditions used to mold PEEK can influence the crystalline and hence the mechanical properties. Its Young’s modulus is 3.6 GPa and its tensile strength is 90 to 100 MPa.[5] PEEK has a glass transition temperature of around 143 °C (289 °F) and melts around 343 °C (662 °F). Some grades have a useful operating temperature of up to 250 °C (482 °F).[3] The thermal conductivity increases nearly linearly with temperature between room temperature and solidus temperature.[6] It is highly resistant to thermal degradation,[7] as well as to attack by both organic and aqueous environments. It is attacked by halogens and strong Bronzed and Lewis acids, as well as some halogenated compounds and aliphatic hydrocarbons at high temperatures. It is soluble in concentrated sulfuric acid at room temperature, although dissolution can take a very long time unless the polymer is in a form with a high surface-area-to-volume ratio, such as a fine powder or thin film. It has high resistance to biodegradation.

PEEK Features

Excellent self-extinguishing, no need to add any flame retardant up to 5VA

Super high temperature resistant grade after glass fiber enhancement

Good self lubricity

Excellent resistance to oil and chemical corrosion

Good dimensional stability

Excellent resistance to creep and fatigue aging

Good insulation and sealing performance

High temperature disinfection

PEEK Main Application Field

PEEK is used to fabricate items for demanding applications, including bearings, piston parts, pumps, high-performance liquid chromatography columns, compressor plate valves, and electrical cable insulation. It is one of the few plastics compatible with ultra-high vacuum applications, which makes it suitable for aerospace, automotive, electronic, and chemical industries.[8] PEEK is used in medical implants, e.g., use with a high-resolution magnetic resonance imaging (MRI), for creating a partial replacement skull in neurosurgical applications.

PEEK is used in spinal fusion devices and reinforcing rods.[9] It is radiolucent, but it is hydrophobic causing it to not fully fuse with bone.[8] [10] PEEK seals and manifolds are commonly used in fluid applications. PEEK also performs well in high temperature applications (up to 500 °F/260 °C).[11] Because of this and its low thermal conductivity, it is also used in FFF printing to thermally separate the hot end from the cold end.

| Field | Application Cases |

| Automotive aerospace | Automobile seal ring, bearing fittings, engine fittings, bearing sleeve, air intake grille |

| Electrical and electronic field | Mobile phone gasket, dielectric film, High temperature electronic element, high-temperature connector |

| Medical and other fields | Medical precision instrument, Artificial skeletal structure, Electric cable pipe |

Grade Equivalent List

| Material | Specification | SIKO grade | Equivalent to Typical brand & grade |

| PEEK | PEEK Unfilled | SP990K | VICTREX 150G/450G |

| PEEK Monofilament extrusion grade | SP9951KLG | VICTREX | |

| PEEK+30% GF/CF(Carbon fiber) | SP990KC30 | SABIC LVP LC006 |

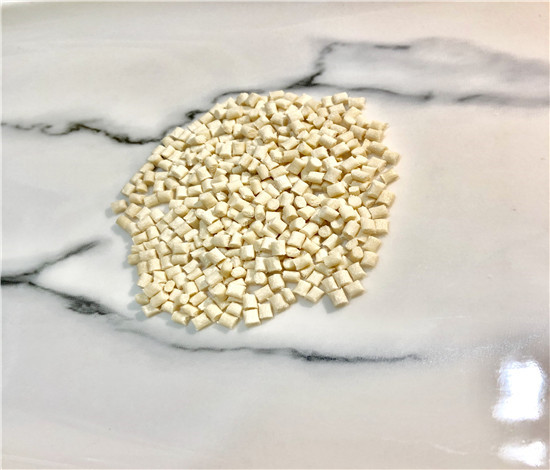

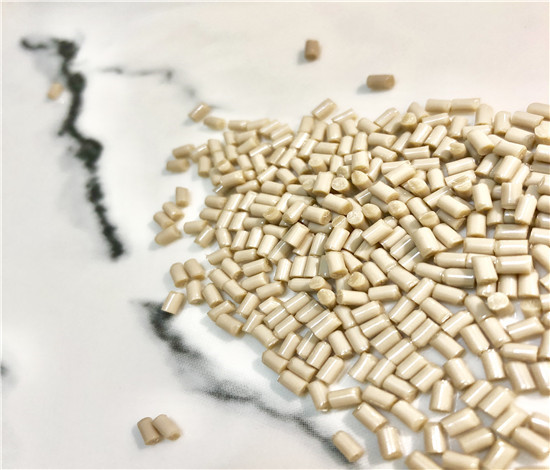

Product detail pictures:

Related Product Guide:

We emphasize enhancement and introduce new solutions into the market just about every year for China Cheap price Polyamide Resin - Material plastic PEEK-UNFILLED GF, CF for power tools – Siko , The product will supply to all over the world, such as: Nepal, Qatar, Ireland, It using the world's leading system for reliable operation, a low failure rate, it suitable for Argentina customers choice. Our company is situated within the national civilized cities, the traffic is very convenient, unique geographical and economic conditions. We pursue a people-oriented, meticulous manufacturing, brainstorm, build brilliant" business philosophy. Strict quality management, perfect service, reasonable price in Argentina is our stand on the premise of competition. If necessary, welcome to contact us by our website or phone consultation, we will be happy to serve you.

The quality of the products is very good, especially in the details, can be seen that the company work actively to satisfy customer's interest, a nice supplier.