China wholesale Biodegradable Injection Molding Raw Material - Biodegradable Blister Modified Material – Siko

China wholesale Biodegradable Injection Molding Raw Material - Biodegradable Blister Modified Material – Siko Detail:

SPLA-IM116 Features

The main components of the product are PLA, PBAT and inorganic substances, and its products can be 100% biodegraded after use and waste, and ultimately generate carbon dioxide and water, without polluting the environment. This type of product has high melt strength and low melt index, and is especially suitable for sheet extrusion processing and applications in the blister box industry. The product has the characteristics of stable melting finger, high melt strength, good processing performance and excellent mechanical properties.

SPLA-IM116 Main Application Field

It can be directly used in fully biodegradable disposable blister hot and cold lunch boxes and trays, and can be directly extruded to make business cards, cards, etc.

SPLA-IM116 Grades And Description

| Grade | Description | Processing Instructions |

| SPLA-IM116 | The main components of the product are PLA, PBAT and inorganic substances, and its products can be 100% biodegraded after use and waste, and ultimately generate carbon dioxide and water, without polluting the environment. | When using the modified product on an extruded sheet production line, the recommended extrusion processing temperature is 180-200℃. |

Grade Equivalent List

| Field | GF&CF reinforced |

| Auto Parts | Radiators, cooling fan, door handle, fuel tank cap, air intake grille, water tank cover, lamp holder |

| Auto Parts | Radiators, cooling fan, door handle, fuel tank cap, air intake grille, water tank cover, lamp holder |

| Auto Parts | Radiators, cooling fan, door handle, fuel tank cap, air intake grille, water tank cover, lamp holder |

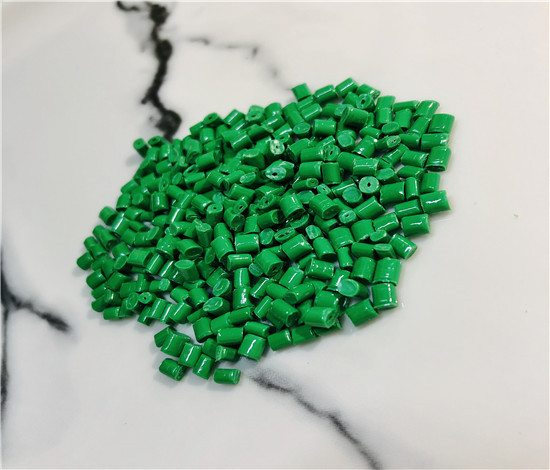

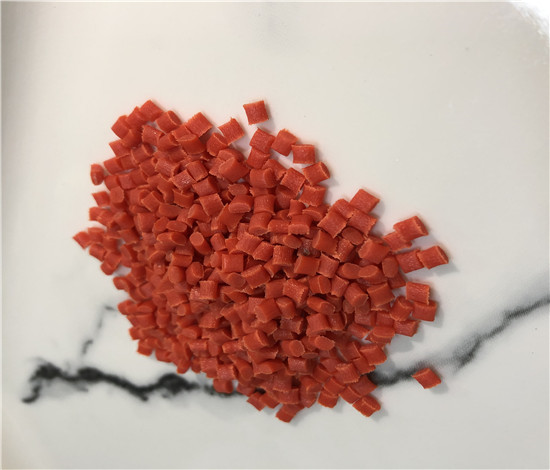

Product detail pictures:

Related Product Guide:

The key to our success is "Good Product or service High quality, Reasonable Rate and Efficient Service" for China wholesale Biodegradable Injection Molding Raw Material - Biodegradable Blister Modified Material – Siko , The product will supply to all over the world, such as: Seychelles, Sevilla, Sri Lanka, Products have been exported to Asia, Mid-east,European and Germany market. Our company has constantly been able to update the products performance and safety to meet the markets and strive to be top A on stable quality and sincere service. If you have the honor to do business with our company. we will definitely do our very best to support your business in China.

Staff is skilled, well-equipped, process is specification, products meet the requirements and delivery is guaranteed, a best partner!