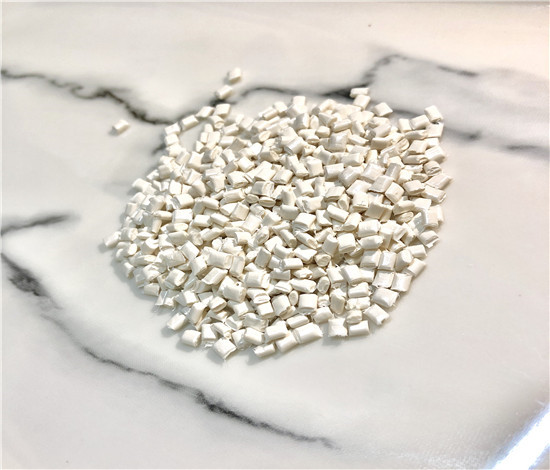

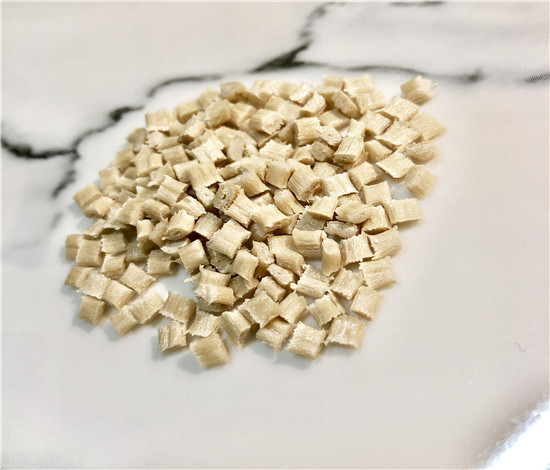

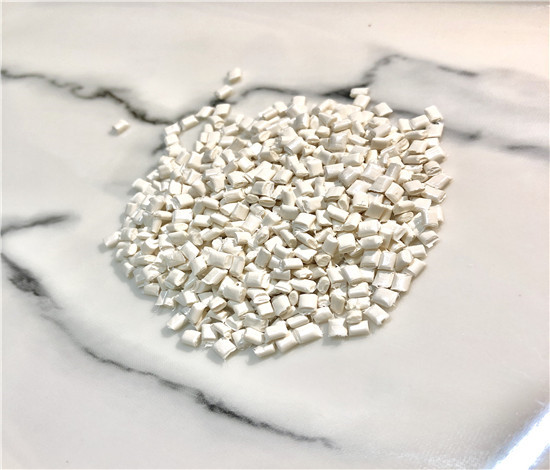

Engineering plastics heat resistant PPA-GF, FR for breaker and bobbins

Polyphthalamide (aka. PPA, High Performance Polyamide) is a subset of thermoplastic synthetic resins in the polyamide (nylon) family defined as when 55% or more moles of the carboxylic acid portion of the repeating unit in the polymer chain is composed of a combination of terephthalic (TPA) and isophthalic (IPA) acids. The substitution of aliphatic decides by aromatic decides in the polymer backbone increases the melting point, glass transition temperature, chemical resistance and stiffness.

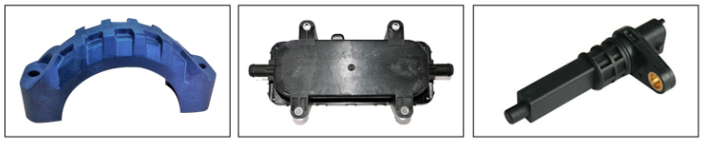

PPA based resins are molded into parts to replace metals in applications requiring high temperature resistance such as automotive power train components, the housing for high temperature electrical connectors and many other uses.

The glass transition temperature of PPA increases as the amount of TPA increases. If more than 55% of the acid part of a PPA is made out of IPA, then the copolymer is amorphous. The properties of semi crystalline polymers v amorphous polymers are described elsewhere in detail. Briefly, crystalline helps with chemical resistance and mechanical properties above the glass transition temperature (but below the melting point). Amorphous polymers are good in warpage and transparency.

PPA Features

PPA material has excellent combination properties, which performs well at thermal, electrical, physical and chemical properties. Especially under high temperature PPA still has high rigidity and high strength, together with excellent dimensional accuracy and stability.

PPA Main Application Field

Special using grade for Automotive water temp control assembly and thermostat body part.

| Field | Application Cases |

| Auto Parts | Auto Water Temperature Control Assemblies, thermostat body part, structure parts, dynamic pump, clutch part, oil pump etc. |

| Electronic and Electrical | Connector, SMT connector, Breaker, socket, bobbins etc. |

| Precision industry and mechnical parts | Power steering pump parts, steam oven parts, hot water boiler connectors, water heater accessories |

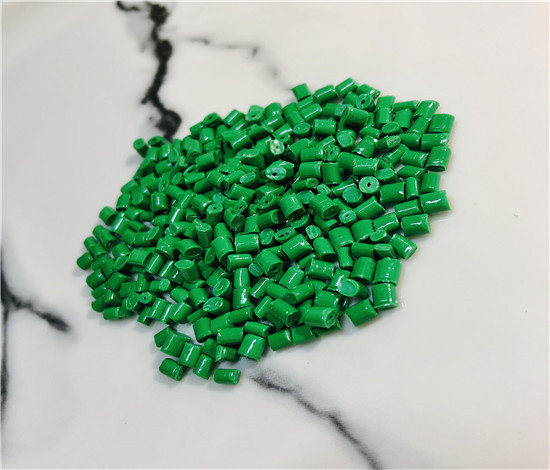

SIKO PPA Grades And Description

| SIKO Grade No. | Filler(%) | FR(UL-94) | Description |

| SPA90G33/G40-HRT | 33%-40% | HB | PPA, is a kind of semi-crystalline thermoplastic aromatic polyamide, commonly named as high-temperature resistant aromatic nylon, with a property of heat resistant 180℃ in long-term working temperature, and 290℃ in short-term working temperature, as well as high modulus, high rigidity, high performance-price ratio, low water absorption rate, dimensional stability and excellent welding advantage, etc. PPA material has excellent combination properties, which performs well at thermal, electrical, physical and chemical properties. Especially under high temperature PPA still has high rigidity and high strength, together with excellent dimensional accuracy and stability. |

| SPA90G30/G35/40/45/50 | 30%,35%,40

%,45%,50% |

HB | |

| SPA90G30F/G35F/40F/45F/50F | 30%,35%,40

%,45%,50% |

V0 | |

| SPA90G35F-GN | 35% | V0 | |

| SPA90G35-WR | 35% | HB | |

| SPA90C35/C40 | 35%,40% | HB |

Grade Equivalent List

| Material | Specification | SIKO grade | Equivalent to Typical brand & grade |

| PPA | PPA+33%GF, Heat stabilized, Hydrolysis, HB | SPA90G33-HSLR | SOLVAY AS-4133HS,DUPONT HTN 51G35HSLR |

| PPA+50%GF, Heat stabilized, HB | SPA90G50-HSL | EMS GV-5H, DUPONT HTN 51G50HSL | |

| PPA+30%GF, FR V0 | SPA90G30F | SOLVAY AFA-6133V0Z, DUNPONT HTN FR52G30NH |