Factory Supply Biodegradable And Compostable Bags - Biodegradable 3D Printing Modified Materials – Siko

Factory Supply Biodegradable And Compostable Bags - Biodegradable 3D Printing Modified Materials – Siko Detail:

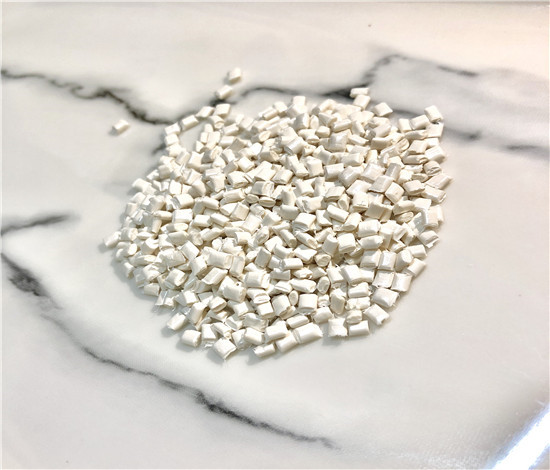

Several technologies such as annealing, adding nucleating agents, forming composites with fibers or nano-particles, chain extending and introducing crosslink structures have been used to enhance the mechanical properties of PLA polymers. Polylactic acid can be processed like most thermoplastics into fiber (for example, using conventional melt spinning processes) and film. PLA has similar mechanical propertiesto PETE polymer, but has a significantly lower maximum continuous use temperature. With high surface energy, PLA has easy printability which makes it widely used in 3-D printing. The tensile strength for 3-D printed PLA was previously determined.

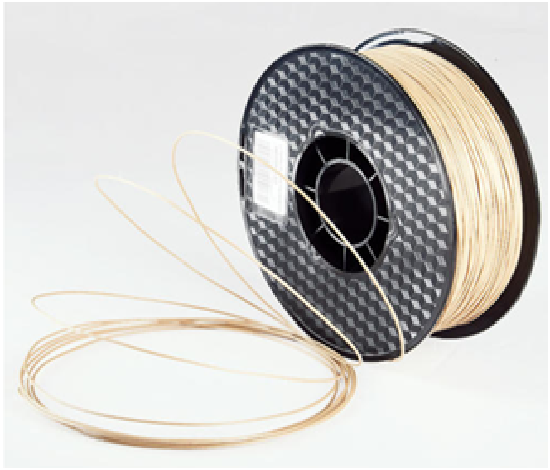

PLA is used as a feedstock material in desktop fused filament fabrication 3D printers . PLA-printed solids can be encased in plaster-like moulding materials, then burned out in a furnace, so that the resulting void can be filled with molten metal. This is known as “lost PLA casting”, a type of investment casting.

SPLA-3D Features

Stable molding

Smooth printing

Excellent mechanical properties

SPLA-3D Main Application Field

High toughness, high strength 3D printing modified material,

Low-cost, high-strength 3D printing modified materials

SPLA-3D Grades And Description

| Grade | Description |

| SPLA-3D101 | High-performance PLA. PLA accounts for more than 90%. Good printing effect andhigh intensity. The advantages are stable forming, smooth printing and excellentmechanical properties. |

| SPLA-3DC102 | PLA accounts for 50-70% and is mainly filled and toughened. The advantages arestable forming, smooth printing andexcellent mechanical properties. |

Product detail pictures:

Related Product Guide:

We believe that prolonged time period partnership is really a result of top of the range, benefit added provider, prosperous knowledge and personal contact for Factory Supply Biodegradable And Compostable Bags - Biodegradable 3D Printing Modified Materials – Siko , The product will supply to all over the world, such as: Algeria, Oman, Azerbaijan, Our company is working by the operation principle of "integrity-based, cooperation created, people oriented, win-win cooperation". We hope we can have a friendly relationship with businessman from all over the world

As an international trading company, we have numerous partners, but about your company, I just want to say, you are really good, wide range, good quality, reasonable prices, warm and thoughtful service, advanced technology and equipment and workers have professional training, feedback and product update is timely, in short, this is a very pleasant cooperation, and we look forward to the next cooperation!