Good Quality Polyamide 6 Resin - High performance plastic MOS2+PA6/PA66/PA46 used in machinery – Siko

Good Quality Polyamide 6 Resin - High performance plastic MOS2+PA6/PA66/PA46 used in machinery – Siko Detail:

MOS2+PA6/PA66/PA46 Features

The main function of MOS2 used for friction material is to reduce friction at low temperature and increase friction at high temperature. The loss of burning is small and volatile in friction material.

Friction reduction: the particle size of MOS2 made by smashing supersonic airflow reaches 325-2500 mesh, the hardness of micro particles is 1-1.5, and the friction coefficient is 0.05-0.1. Therefore, it can play a role in friction reduction in friction materials.

Rammerization: MOS2 does not conduct electricity and there is a copolymer of MOS2, MOS3 and MoO3. When the temperature of the friction material rises sharply due to friction, MoO3 particles in the copolymer expand with the temperature rising, playing a role of friction.

Anti-oxidation: MOS2 is obtained by chemical purification synthesis reaction; its PH value is 7-8, slightly alkaline. It covers the surface of the friction material, can protect other materials, prevent them from being oxidized, especially make other materials not easy to fall off, adhesion strength is enhanced

Fineness: 325-2500 mesh;

PH: 7-8;Density: 4.8 to 5.0 g/cm3;Hardness: 1-1.5;

Ignition loss: 18-22%;

Friction coefficient :0.05-0.09

MOS2+PA6/PA66/PA46 Main Application Field

Widely used in machinery, instrumentation, automotive parts, electrical and electronic, railway, home appliances, communications, textile machinery, sports and leisure products, oil pipes, fuel tanks and some precision engineering products.

| Field | Application Cases |

| Electronic appliances | Light emitter, laser, photoelectric detector, |

| Electrical & Electronic parts | Connector, bobbin, timer, cover circuit breaker, switch housing |

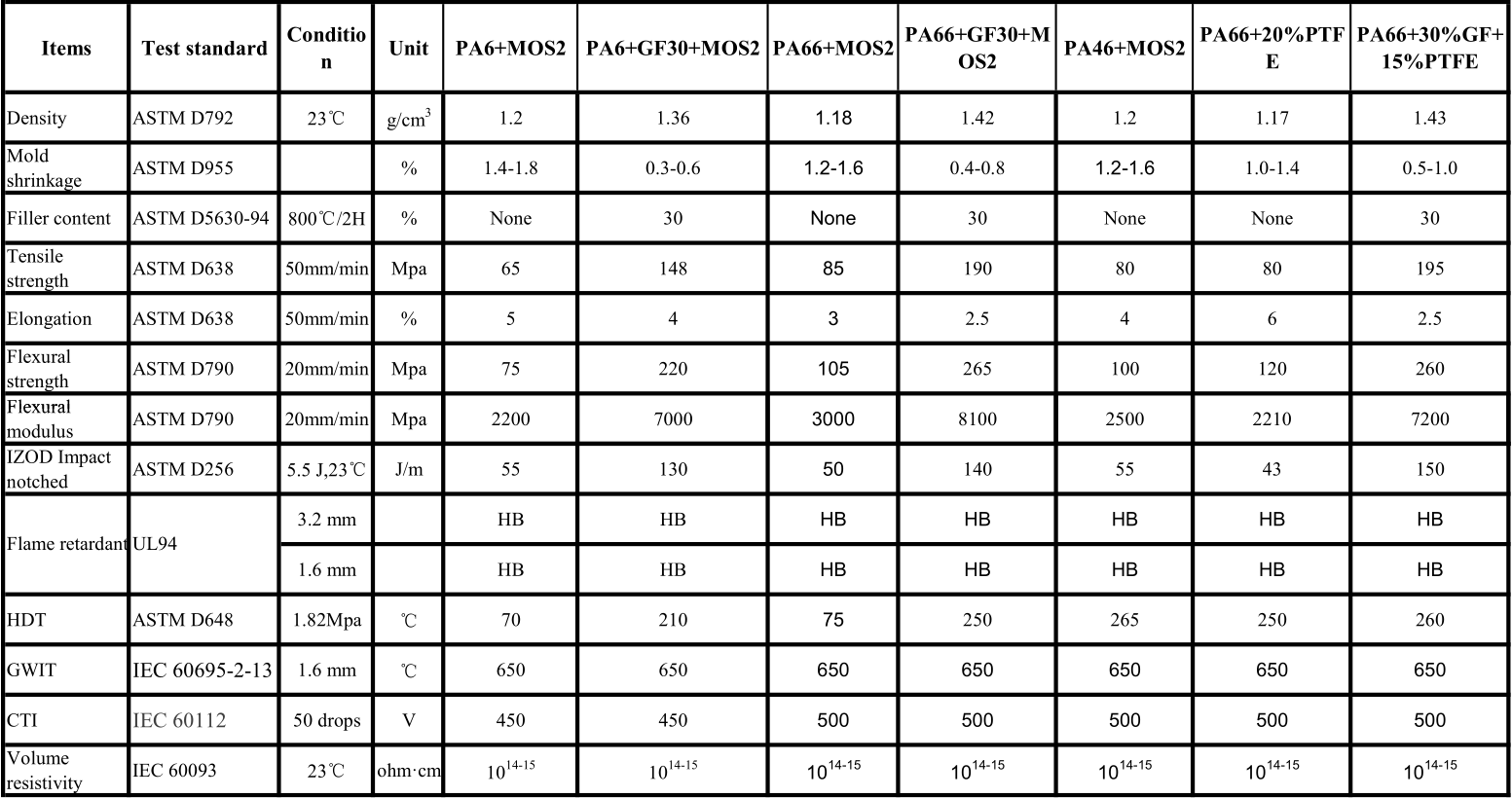

Grade Equivalent List

Product detail pictures:

Related Product Guide:

The really abundant projects administration experiences and just one to one particular provider model make the substantial importance of organization communication and our easy understanding of your expectations for Good Quality Polyamide 6 Resin - High performance plastic MOS2+PA6/PA66/PA46 used in machinery – Siko , The product will supply to all over the world, such as: Argentina, Honduras, Swansea, We welcome customers from all over the world come to discuss business. We supply high quality products, reasonable prices and good services. We hope to sincerely build business relationships with customers from at home and abroad, jointly striving for a resplendent tomorrow.

This is a very professional and honest Chinese supplier, from now on we fell in love with the Chinese manufacturing.