Hot sale Polypropylene Fire Retardant - high mechanical properties PEI- Unfilled, GF, CF for industrial products cover – Siko

Hot sale Polypropylene Fire Retardant - high mechanical properties PEI- Unfilled, GF, CF for industrial products cover – Siko Detail:

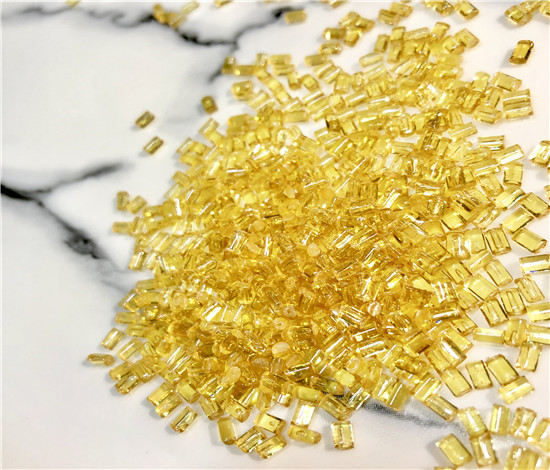

Polyetherimide (PEI) is an amorphous, amber-to-transparent thermoplastic with characteristics similar to the related plastic PEEK. Relative to PEEK, PEI is cheaper, but is lower in impact strength and usable temperature. Because of its adhesive properties and chemical stability it became a popular bed material for FFF 3D printers.

The glass transition temperature of PEI is 217 °C (422°F). Its amorphous density at 25 °C is 1.27 g/cm3(.046 lb/in³). It is prone to stress cracking in chlorinated solvents. Polyetherimide is able to resist high temperatures with stable electrical properties over a wide range of frequencies. This high strength material offers excellent chemical resistance and ductile properties suitable for various applications, even those including steam exposure.

PEI- Unfilled, GF, CF Features

Good heat resistance, super toughness& fatigue resistance.

Nice electrical stability.

Excellent dimension stability,

Self-lubricating, low water absorption,

Electrical insulation is good

To keep good properties in the humid environment .

PEI- Unfilled, GF, CF Main Application Field

Widely used on various electronic and electrical appliances, machinery, automobiles, aerospace and aviation, food and medical supplies, light guide materials and connectors, high-end precision industrial structures, printer accessories, and gear accessories.

SIKO PEI Grades And Description

| SIKO Grade No. | Filler(%) | FR(UL-94) | Description |

| SP701E10/20/30C | 10%-30%GF | V0 | GF Reinforced |

| SP701E | None | V0 | PEI NO GF |

Grade Equivalent List

| Material | Specification | SIKO grade | Equivalent to Typical brand & grade |

| PEI | PEI unfilled, FR V0 | SP701E | SABIC ULTEM 1000 |

| PEI+20%GF, FR V0 | SP701EG20 | SABIC ULTEM 2300 |

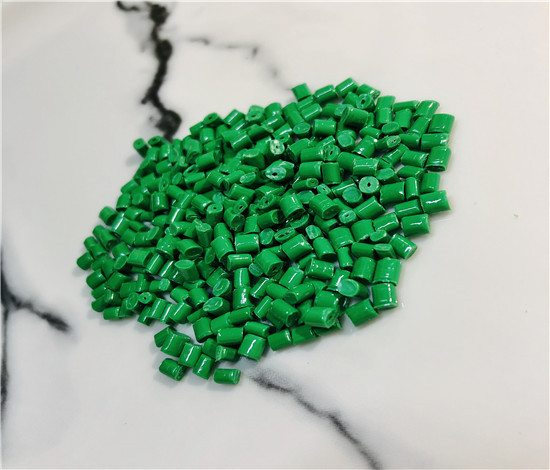

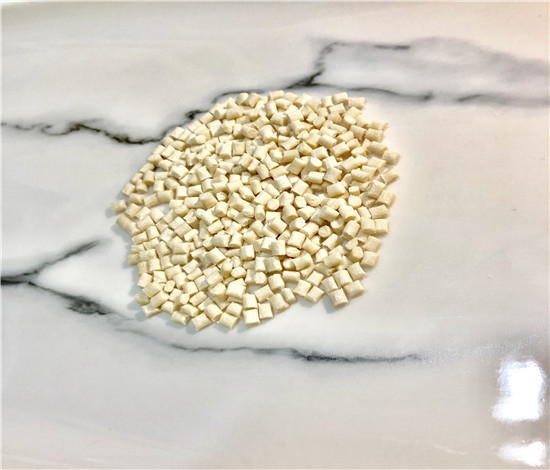

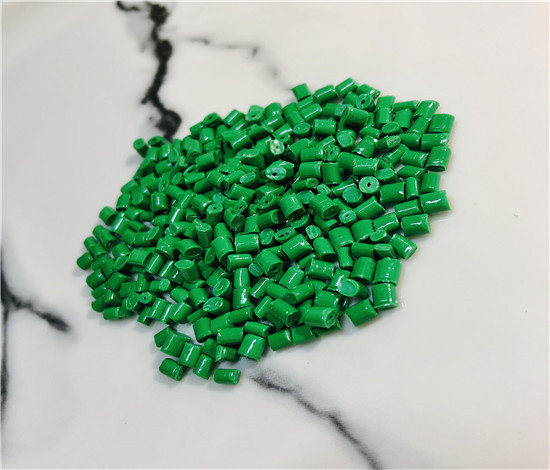

Product detail pictures:

Related Product Guide:

Sticking for the principle of "Super Quality, Satisfactory service" ,We have been striving for being a superb small business partner of you for Hot sale Polypropylene Fire Retardant - high mechanical properties PEI- Unfilled, GF, CF for industrial products cover – Siko , The product will supply to all over the world, such as: US, UAE, Iraq, We strive for excellence, constant improvement and innovation, is committed to make us the "customer trust" and the "first choice of engineering machinery accessories brand" suppliers. Choose us, sharing a win-win situation!

Factory equipment is advanced in the industry and the product is fine workmanship, moreover the price is very cheap, value for money!