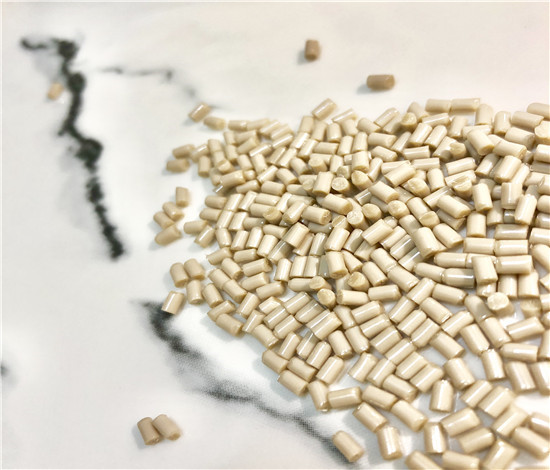

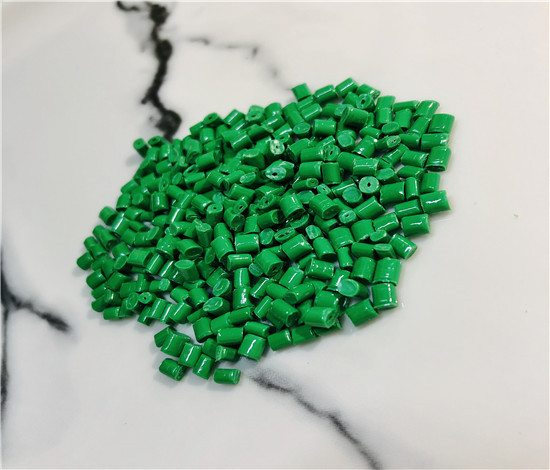

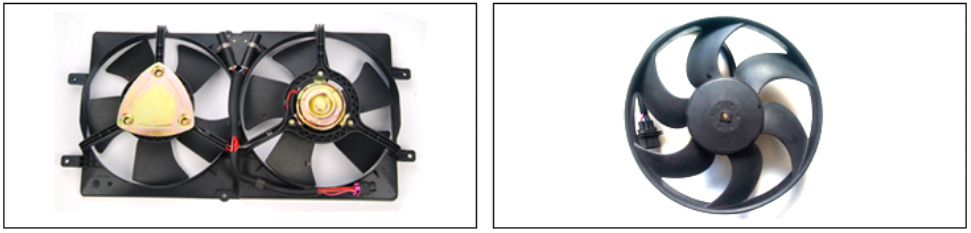

Long glass fiber PP+10%-60% LFT (Long Glass Fiber) for auto front-end modules

PP+10%-60% LFT Features

As a long-fiber thermoplastic resin, it can be used as a substitute for metal and short glass fiber reinforced engineering plastics.The main features are:

Excellent rigidity and impact resistance.

High tensile strength and bending strength.

Long-term mechanical properties (long-term impact resistance and long-term vibration).

Very stable dimensional stability. Excellent (low

shrinkage and small vertical and horizontal),

Extremely high fluidity.

PP+10%-60% LFT Main Application Field

Widely used in machinery, instrumentation, automotive parts, electrical and electronic, railway, home appliances, communications, textile machinery, sports and leisure products, oil pipes, fuel tanks and some precision engineering products.

| Field | Application Cases |

| Automotive | Automotive sector include bumpers, instrument panels, battery brackets, front-end components, electric control boxes, rear door flaps, noise barriers, chassis covers, spare tire compartments, seat support plates |

| Electromechanical field | Motor filter covers, wind blades, coaxial cylinder clutch auxiliary parts, high-lift submersible motors, water pumps, thrust bearings, guide bearings / locomotive guide rails, vacuum pumps, Compressor rotor and other components. |

| Home appliances | LFT-PP materials can be used in washing machine drums, washing machine triangle brackets, one-brush machine drums, air-conditioning fans, etc., with a high cost performance. |

SIKO PP+10%-60% LFT Grades And Description

| SIKO Grade No. | Filler(%) | FR(UL-94) | Description |

| SP60LFT-10/20/30/40/50 | 10-50% | HB | 10%-50% LFT reinforced,high rigidity,

high stregnth |

| SP60LFT-10/20/30/40/50F | V0 |