Low MOQ for Abs V0 - High flow ABS-GF, FR high heat resistance for OA application – Siko

Low MOQ for Abs V0 - High flow ABS-GF, FR high heat resistance for OA application – Siko Detail:

ABS is a terpolymer made by polymerizing styrene and acrylonitrile in the presence of polybutadiene. The proportions can vary from 15% to 35% acrylonitrile, 5% to 30% butadiene and 40% to 60% styrene. The result is a long chain of polybutadiene crises-crossed with shorter chains of poly(styrene-co-acrylonitrile). The nitrile groups from neighboring chains, being polar, attract each other and bind the chains together, making ABS stronger than pure polystyrene. The acrylonitrile also contributes chemical resistance, fatigue resistance, hardness, and rigidity, while increasing the heat deflection temperature. The styrene gives the plastic a shiny, impervious surface, as well as hardness, rigidity, and improved processing ease. The polybutadiene, a rubbery substance, provides toughness and ductility at low temperatures, at the cost of heat resistance and rigidity. For the majority of applications, ABS can be used between −20 and 80 °C (−4 and 176 °F), as its mechanical properties vary with temperature. The properties are created by rubber toughening, where fine particles of elastomer are distributed throughout the rigid matrix.

ABS Features

Low water absorption. ABS combines well with other materials and is easy to surface print and coat.

ABS has excellent mechanical properties and its impact strength is excellent, so it can be used at very low temperatures:

ABS has excellent wear resistance, good dimensional stability and oil resistance.

The heat distortion temperature of ABS is 93~118 °C, and the product can be improved by about 10 °C after annealing. ABS can still exhibit a little toughness at -40 ° C and can be used in the temperature range of -40 to 100 ° C.

ABS has good electrical insulation and is hardly affected by temperature, humidity and frequency.

ABS is not affected by water, inorganic salts, alkalis and various acids.

ABS Main Application Field

|

Field |

Application Cases |

|

Auto Parts |

Car dashboard, body exterior, interior trim, steering wheel, acoustic panel, bumper, air duct. |

|

Home Appliance parts |

Refrigerators, televisions, washing machines, air conditioners, computers, photocopiers, etc. |

|

Other parts |

Automated instrumentation gears, bearings, handles, machine housings |

SIKO ABS Grades And Description

|

SIKO Grade No. |

Filler(%) |

FR(UL-94) |

Description |

|

SP50-G10/20/30 |

10%-30% |

HB |

10%-30% Glassfiber reinforced, high strength. |

|

SP50F-G10/20/30 |

10%-30% |

V0 |

10%-30% Glassfiber reinforced, high strength, FR V0@1.6mm. |

|

SP50F |

None |

V0,5VA |

General strength, high flowablity, FR V0@1.6mm. High heat resistance, High gloss, Anti-UV properies are avaliable. |

Grade Equivalent List

|

Material |

Specification |

SIKO grade |

Equivalent to Typical brand & grade |

|

ABS |

ABS FR V0 |

SP50F |

CHIMEI 765A |

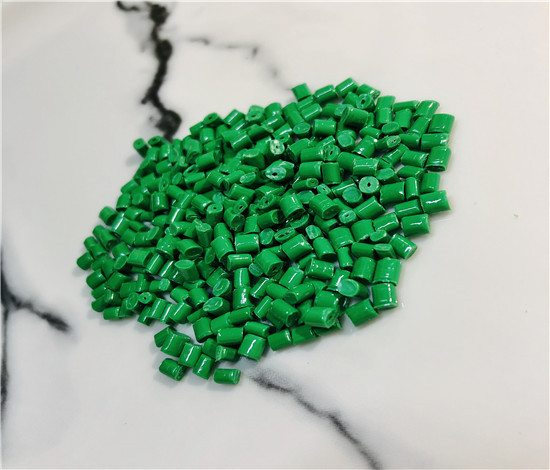

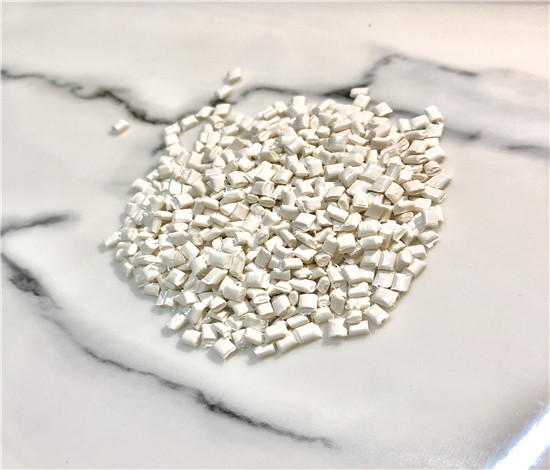

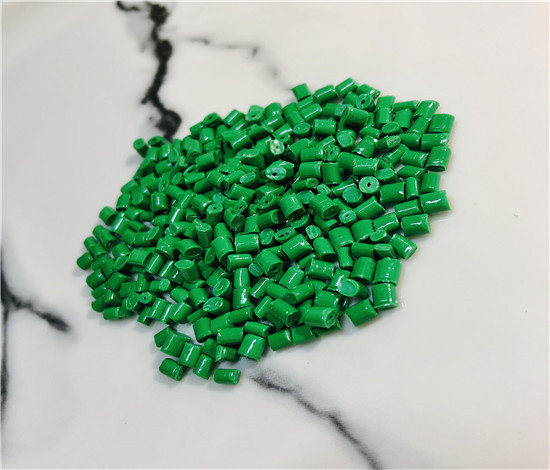

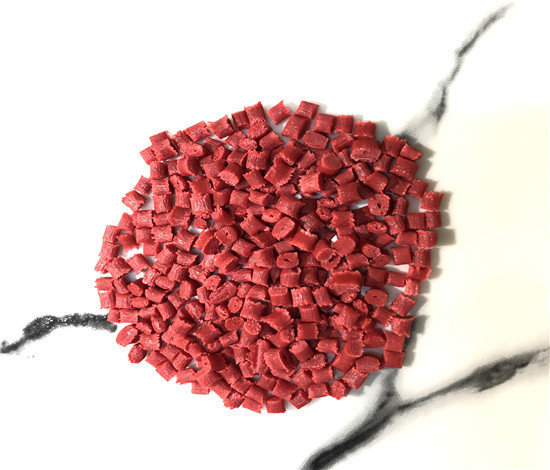

Product detail pictures:

Related Product Guide:

Our organization promises all customers with the first-class products and solutions and the most satisfying post-sale service. We warmly welcome our regular and new clients to join us for Low MOQ for Abs V0 - High flow ABS-GF, FR high heat resistance for OA application – Siko , The product will supply to all over the world, such as: Seattle, New York, Nigeria, Satisfaction and good credit to every customer is our priority. We focus on every detail of order processing for customers till they have received safe and sound solutions with good logistics service and economical cost. Depending on this, our solutions are sold very well in the countries in Africa, the Mid-East and Southeast Asia.

This is a very professional and honest Chinese supplier, from now on we fell in love with the Chinese manufacturing.