Manufacturer for Environmentally Degradable Plastics – Outstanding material PC+ABS/ASA for laptop computers – Siko

Manufacturer for Environmentally Degradable Plastics – Outstanding material PC+ABS/ASA for laptop computers – Siko Detail:

PC+ABS/ASA Features

Good comprehensive performance, high impact strength, chemical stability, good electrical performance.

Good welding property with 372 plexiglass, made of two-color plastic parts, and can be chrome plated, spray paint treatment.

High impact resistance, high heat resistance, flame retardant, enhancement, transparency and other levels.

Liquidity is less than HIPS, better than PMMA, PC, etc., good flexibility.

Excellent balance of mechanical properties

Low temperature also has high impact strength

Indoor uv stability

High thermal deformation temperature (80 ~ 125℃)

Fire resistance (UL945VB)Wide range of colors

Easy injection molding and extrusion, blow molding processing

Good electroplating property

The general density is between 1.05 and 1.20

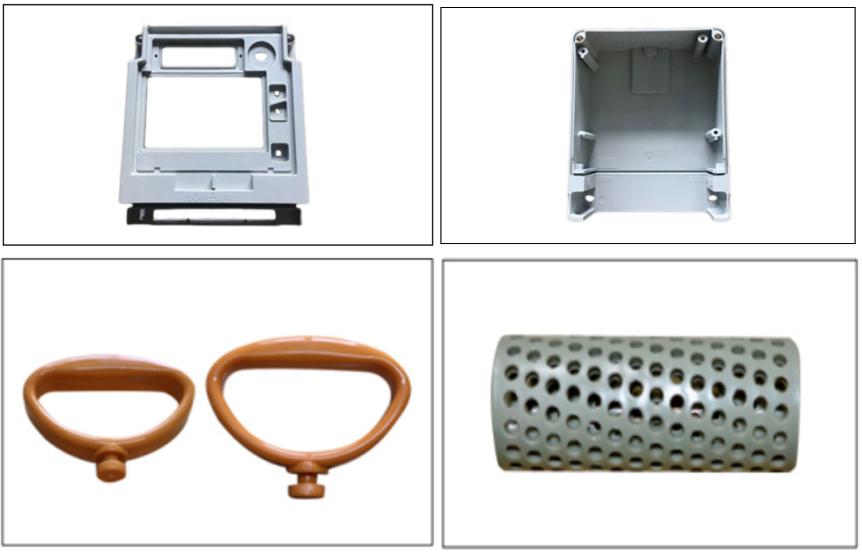

PC+ABS/ASA Main Application Field

Widely used in machinery, instrumentation, automotive parts, electrical and electronic, railway, home appliances, communications, textile machinery, sports and leisure products, oil pipes, fuel tanks and some precision engineering products.

|

Field |

Application Cases |

|

OA systems |

laser printers, inkjet printers, fax machines, laptop computers, and digital toys |

SIKO PC+ABS/ASA Grades And Description

|

SIKO Grade No. |

Filler(%) |

FR(UL-94) |

Description |

|

SP150 |

None |

HB |

PC/ABS is the most mature alloy material, and on the basis of retaining most of the mechanical properties of PC materials, it has better improved the poor flowability of PC materials. At the same time, halogen-free flame retardant PC/ABS materials are currently in OA systems such as laser printers, inkjet printers, fax machines, laptop computers, and digital toys. PC/ASA has better weatherability than PC/ABS and is more suitable for outdoor products. |

|

SP150F |

None |

V0 |

|

|

SP150F-G10/G20 |

10%,20% |

V0 |

Grade Equivalent List

| Material | Specification | SIKO grade | Equivalent to Typical brand & grade |

| PC | PC/ABS Alloy | SP150 | COVESTRO Bayblend T45/T65/T85, SABIC C1200HF |

| PC/ABS FR V0 | SP150F | SABIC CYCOLOY C2950 | |

| PC/ASA Alloy | SPAS1603 | SABIC GELOY XP4034 |

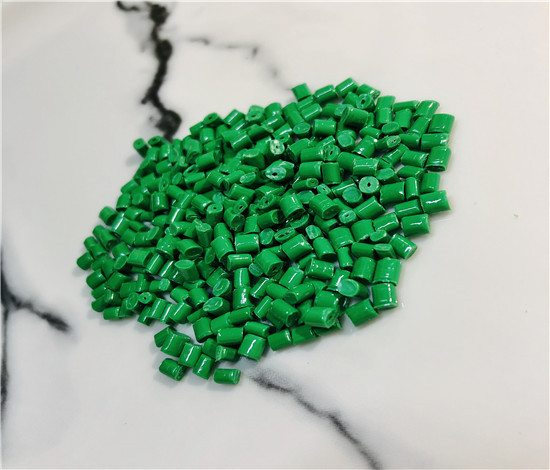

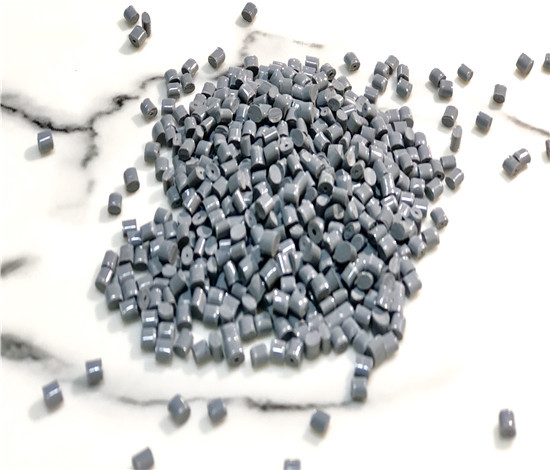

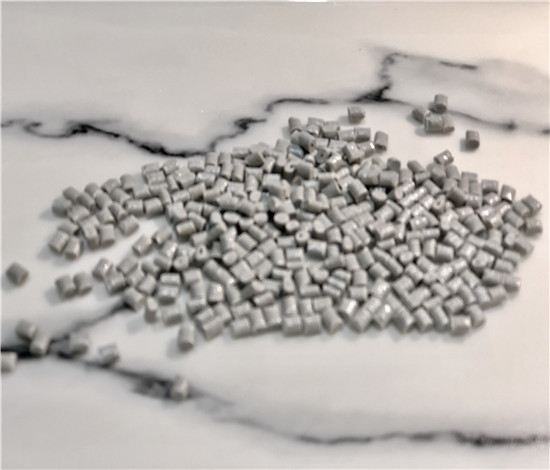

Product detail pictures:

Related Product Guide:

Our pursuit and company goal is to "Always satisfy our customer requirements". We continue to develop and design superior quality products for both our old and new customers and achieve a win-win prospect for our clients as well as us for Manufacturer for Environmentally Degradable Plastics – Outstanding material PC+ABS/ASA for laptop computers – Siko , The product will supply to all over the world, such as: Germany, moldova, Rwanda, Many kinds of different solutions are available for you to choose, you can do one-stop shopping here. And customized orders are acceptable. Real business is to get win-win situation, if possible, we would like to deliver more support for customers. Welcome all nice buyers communicate details of solutions with us!!

Good quality and fast delivery, it's very nice. Some products have a little bit problem, but the supplier replaced timely, overall, we are satisfied.