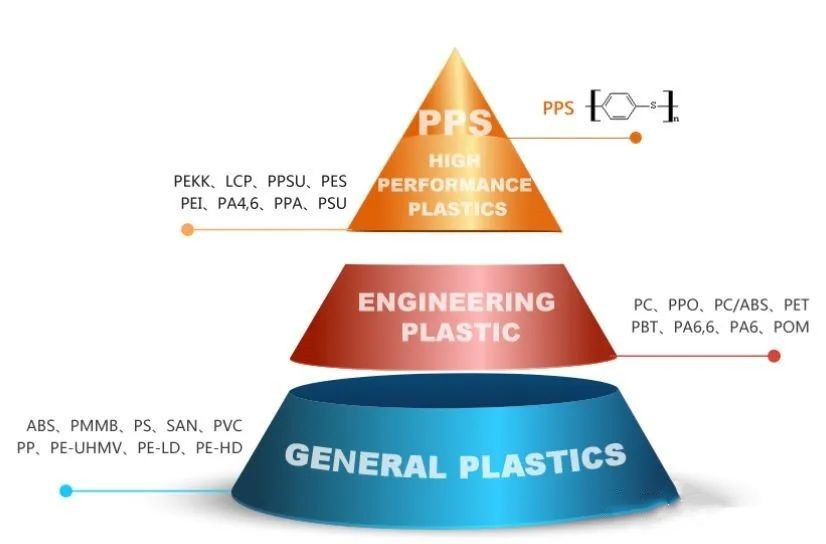

Polyphenylene sulfide(PPS), with a symmetrical rigid backbone, is a partially crystalline polymer consisting of repeating para-substituted benzene rings and sulfur atoms. PPS is a special engineering plastic with high performance and a high melting point of up to 280 ℃, which can be metal replacement. The excellent properties of PPS resin make it meet the material requirements of demanding automotive parts.

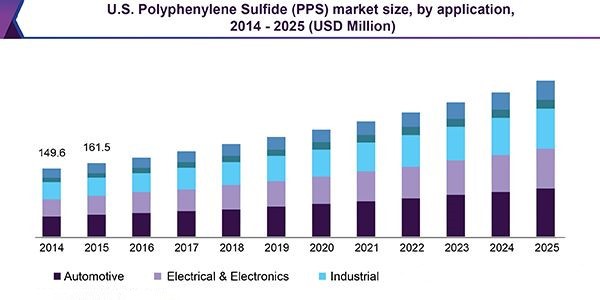

PPS has a wide range of applications in the automotive industry, and the demand for PPS in auto-manufacturing countries such as India, China, and Japan is increasing to meet the requirements for lightweight and stability of automobiles.

PPS resin has the following excellent properties:

1. Inherent flame retardancy, UL94:V-0/5VA grade without adding flame retardant;

2. Excellent chemical resistance, reaching the degree of solvent-free dissolution below 200 ℃, similar to the chemical resistance level of PTFE;

3. Good dimensional stability, low molding shrinkage and linear expansion coefficient; due to low water absorption, excellent dimensional stability can also be maintained in high-humidity and high-temperature environments

4. Outstanding mechanical properties, high strength and high rigidity, it can maintain fatigue resistance and creep resistance in various environments;

5. Excellent heat resistance, UL temperature index (RTI): 200-220℃, HDT (heat distortion temperature)>260℃.

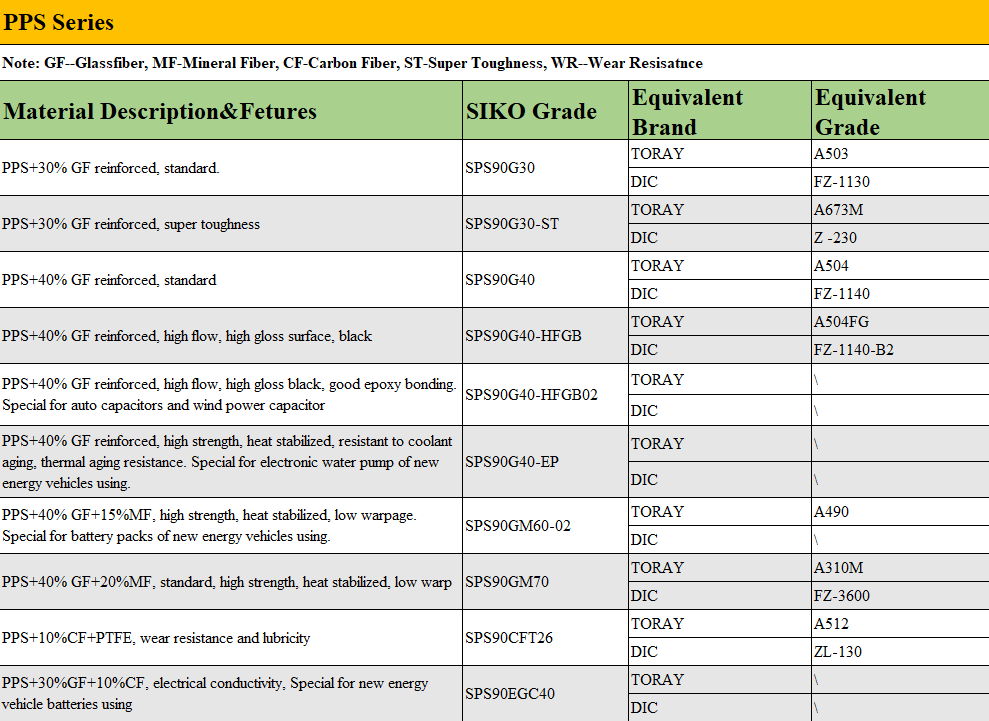

Pure PPS is rarely used alone due to its brittleness. The applied PPS is mostly its modified variety, which is usually modified by adding glass fiber. The following table lists the relevant applications of typical PPS modified resins in the automotive field:

| Material Description | Main Characters | Applications |

| PPS+40%GF | 40% glass fiber reinforced, high strength, high rigidity, high heat resistance, oil and chemical resistance, good dimensional stability | Pump impellers, valve housings and bushings, coil throughs, gearboxes, circuit breakers, lamp sockets, lamp reflector cups and brackets, junction boxes, automotive fuel systems, etc. |

| PPS+65%(GF+MF) | 65% glass fiber/mineral reinforced, excellent dimensional stability, high heat resistance, high stiffness, high surface finish | Mixing valve connectors, high temperature reflectors, pump housings, lamp assemblies, etc. |

| PPS+30%CF | 30% carbon fiber reinforced, high electrical and thermal conductivity, long-term antistatic, high strength | Fan Blades, Brake Sleeves, Model Structure Rotor Blades, Clutch Components, Bushings, etc. |

| PPS+30%GF+15%PTFE | 30% glass fiber reinforced, 15% PTFE lubricated, high thermal deformation stability, flame retardancy, high strength, low creep, improved friction, excellent wear resistance | Injectors, manifolds, pumps, pistons, gears, V-ring gaskets, bearings, control discs, gears, impeller pumps, automotive electrical gear parts, etc. |

| Cooling PPS | Thermal conductivity, electrical insulation, flame retardant, UL94 V0, good strength and toughness | Heat sinks, motor components, LED sockets, thermal circuit boards, cooling components, etc. |

SIKOPOLYMERS’ Main grades of PPS and their equivalent brand and grade, as following:

Post time: 15-08-22