Light diffusion PC, also known as polycarbonate light-diffusing plastic, is a kind of light-transmitting opaque polymerized by a special process with transparent PC (polycarbonate) plastic as the base material, adding a certain proportion of light-diffusing agent and other additives. of light diffusing material particles. With the rapid development of the LED industry in the past ten years, LED lighting has been fully popularized and accepted by people.

Light diffusion PC features:

1, High transmittance, high diffusion, no glare, no shadow of the optical grade PC raw materials.

2, Aging resistance, flame retardant, UV resistance linear.

3, Can be extruded, can also be injection, easy to use and low loss.

4, Excellent concealment of light source, no light spot.

5, With high impact strength.

6, Suitable for LED bulbs, tubes, light penetration plate, housing and other use of LED lighting lampshade special light diffusion material.

In view of the excellent stability and safety of light diffusivity using PC light diffusing plastic, it is currently widely used in commercial lighting, public safety lighting, vehicles and facilities;

Application of light diffusion PC on diffuser plate

At present, PC diffuser plates are mostly used for high-quality LED lighting products, and most of these products are mainly exported. Several major raw material manufacturers mainly use functional PC diffusers for markets with special requirements; Korean and Chinese companies use LED lighting. domain-based.

PC diffuser plate is also called diffused polycarbonate plate, also known as PC light diffuser plate, PC uniform light plate, PC diffuse reflection plate, etc. The base material is polycarbonate (Polycarbonate), which is formed into a diffuser plate by injection molding or extrusion. The technological development of PC diffuser plate originated from raw material manufacturers in developed countries such as Europe, America and Japan. At first, it was developed for the purpose of supporting LED backlight display. With the development of LED lighting, the application of PC diffuser plate in the lighting field also came as the times require.

Application of light diffusion PC in LED bulb

The LED bulb adopts the existing interface methods, namely screw and socket, and even imitates the shape of the incandescent bulb in order to meet people’s usage habits. Based on the unidirectional light-emitting principle of LEDs, designers have made changes to the lamp structure so that the light distribution curve of LED bulbs is basically the same as the point light source of incandescent lamps. Based on the light-emitting characteristics of LEDs, the structure of LED bulbs is more complex than that of incandescent lamps, and is basically divided into light sources, driving circuits, and heat sinks. The cooperation of these parts can create LED bulbs with low energy consumption, long life, high luminous efficiency and environmental protection. lamp products. Therefore, LED lighting products are still high-tech lighting products with high technical content. The materials currently used in LED lighting are basically PC light diffusing materials.

Application of light diffusion PC in plastic-clad aluminum

Reasons for plastic-clad aluminum:

Compared with traditional lighting products, LED lighting products need to focus on heat dissipation. If the heat dissipation problem is not solved, it will directly affect the performance of the lamp beads, thereby shortening the life of the finished lamp. The best heat dissipation is metal such as copper, aluminum, iron, etc., especially aluminum is the most popular, because aluminum is not only light in texture, but also has better thermal conductivity. However, the price of aluminum is relatively expensive, the cost is relatively high, and due to the limitation of the process, there are fewer styles. Secondly, plastics are widely used. Plastics have better insulation and heat dissipation performance, and the price is relatively low, but the thermal conductivity is worse than that of metal, and the appearance of the product is relatively rough and the appearance is not high.

Advantages of plastic-clad aluminum applications:

After comprehensively evaluating the advantages and disadvantages of aluminum and plastics, material manufacturers have developed and launched a new “plastic-clad aluminum” heat dissipation material using light diffusion PC. The outer layer of this Light diffusion PC heat-dissipating material is made of high thermal conductivity plastic, and the inner layer is made of aluminum, which fully considers and combines the advantages of plastic and aluminum. At the same time, this “plastic-coated aluminum” heat dissipation material is cheaper than aluminum and can be recycled. “Plastic-coated aluminum” heat dissipation material can pass safety certification because of its plastic insulating properties, and its safety performance has been improved. It also supports non-isolated power supply and even linear IC drive, which directly affects the technology research and development in the field of power supply.

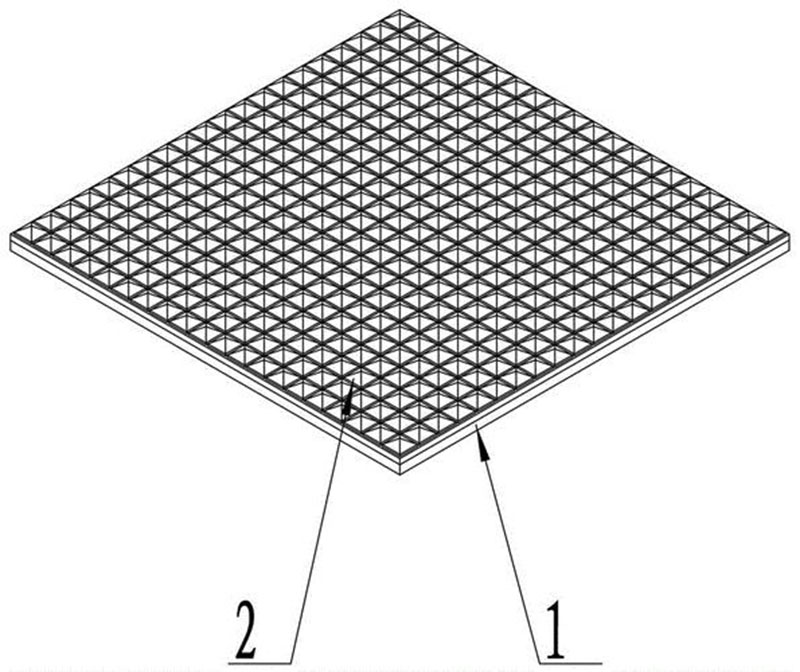

With the development of the LED lighting industry, the technology of light diffusion PC is also constantly innovating. In recent years, new breakthroughs have been made: the technology that mainly realizes the diffusion function through the surface microstructure and supplemented by the diffusion particles has replaced the traditional The technology of diffused particles to realize light diffusion not only meets the high light efficiency of LED lighting, but also gives LED lighting anti-glare function. When the LED lamps light up the lighting, they will emit glare, which will affect people’s comfort and easily cause fatigue. The PC light diffusion plate is adjusted by the surface microstructure to eliminate glare and protect people’s health (the picture below is the PC light diffusion plate. surface structure).

Post time: 22-09-22