(1) The impact of raw materials

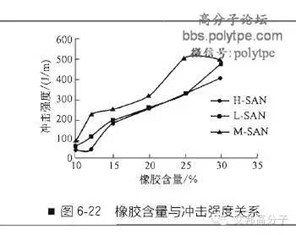

Different brands of PC and ABS resin blend of the alloy has a great difference in performance. It can be seen from Figure 6-22 that high rubber content improves the impact strength of PC/ABS system, but greatly damages the mutual capacitance behavior between the phases, thus reducing the tensile properties of the alloy. Therefore, selecting ABS with appropriate rubber content can not only improve the impact strength of the blend, but also enhance its bending strength synergistically. When ABS with low rubber content is used, the bending strength of the alloy will appear synergistic enhancement. In addition, high acrylonitrile, low rubber content and high molecular weight ABS can improve the heat resistance of the alloy.

(2) The influence of PC/ABS blend ratio on the properties of the alloy

The compatibility and mechanical properties of PC/ABS blend system are directly related to the content of each component in the system. Cao Mingan et al. obtained various PC/ABS alloys with different characteristics by adjusting the blending ratio of PC and ABS resin. The properties of PC/ABS alloy have a linear relationship with the content of ABS, and approximately obey the additivity. The overall properties of PC/ABS alloy are between PC and ABS, and the impact strength has the superadditivity effect (i.e. synergy effect) and antagonism effect with the proportion.

(3) The effect of the third component

The heat resistance and thermal stability of PC/ABS alloy can be improved by adding benzothiazole and polyimide. The fluidity of PC/ABS alloy can be improved by adding processing modifiers such as ethylene oxide/propylene oxide block copolymer, MMA/St copolymer and olefin/acrylic vinegar copolymer. In addition, in order to improve the joint strength of PC/ABS alloy injection products, PMMA, SAN, SBR, acrylic vinegar elastomer, low density polyolefin, ethylene/acrylic vinegar/acetic acid, ethylene (vinegar) copolymer, PC/ ethylene block or graft copolymer and other substances are usually added.

(4) The impact of processing technology

PC and ABS blending equipment can choose from a twin screw extruder and a single screw extruder with a static mixer. Jong Han Chun believes that the effect of continuous kneading extruder is ideal. In terms of blending mode, the effect of second-order blending is better. However, in the second order blending, part of the materials need to be extruded twice at high temperature, which has high energy consumption, easy to degrade the materials and reduce the properties of the alloy.

The molding method also has a great influence on the morphology and structure of PC/ABS alloy. For example, the specimen formed by pressing plastic can better maintain the microstructure heterogeneous dispersion state formed by alloy mixing, while injection molding, at a high shear rate, the dispersion state changes and reaches excessive uniform decomposition. Therefore, the impact strength of the two samples has a great difference, and the impact strength of the compression molding sample is high. PC in water (water content is greater than 0.03%) and high temperature (temperature is higher than 150℃) under easy degradation, so in the blend or molding before drying, should also avoid stearic acid lubricants mixed, so as not to affect the performance of products.

Post time: 02-06-22