News

-

SIKO PPA Successful cases of metal replacement

With the rapid development of the automobile industry, especially the rapid development of new energy vehicles in recent years, the demand for light weight, integration, miniaturization and electrification of auto parts is also increasing. In the field of new energy, the...Read more -

A very complete list of commonly used plastic injection technical parameters, please take good!

Plastic must be thoroughly dried before forming. After the material containing water enters the mold cavity, the surface of the parts will appear silver sash defect, and even the phenomenon of water decomposition will occur at high temperature, resulting in deterioration of the material. Therefo...Read more -

Know something about the molding process of composite materials(Ⅰ)

Composite material forming technology is the basis and condition of the development of composite material industry. With the widening of the application field of composite materials, composite industry has been developing rapidly, some molding process is improving, new molding methods continue t...Read more -

Application progress of special engineering plastics polyether ether ketone (PEEK)

Polyether ether ketone (PEEK) was first developed by Imperial Chemical (ICI) in 1977 and officially sold as VICTREX®PEEK in 1982. In 1993, VICTREX acquired ICI production plant and became an independent company. Weigas has the widest range of poly (ether ketone) products on the market, with a cur...Read more -

Factors affecting properties of PCABS alloy

(1) The impact of raw materials Different brands of PC and ABS resin blend of the alloy has a great difference in performance. It can be seen from Figure 6-22 that high rubber content improves the impact strength of PC/ABS system, but greatly damages the mutual capacitance behavior between the ph...Read more -

Study on flame-retardancy enhancement of PA66 by red phosphorus coated with different resins

Nylon 66 has good mechanical properties, wear resistance and chemical corrosion resistance, and is widely used in automotive, electronic and electrical fields. However, PA66 is flammable material, and there will be droplet when burning, which has a great safety risk. Therefore, it is of great sig...Read more -

Special Engineering Plastic

Special engineering plastics refer to engineering plastics with high comprehensive properties and long-term service temperature above 150℃. Generally both high temperature resistance, radiation resistance, hydrolysis resistance, weather resistance, corrosion resistance, natural flame retardant, l...Read more -

Introduction to the basic knowledge of injection mold design

I. Design basis Dimensional accuracy and accuracy of related dimensions According to the specific requirements and functions of the whole product of plastic products to determine the external quality and specific size belong to which kind: plastic products with higher appearance quality requireme...Read more -

Do you know about the application and modification of PLA open-hole material

Polymer porous material is a polymer material with numerous pores formed by gas dispersed in the polymer material. This special porous structure is very good for the application of sound-absorbing materials, separation and adsorption, drug sustained release, bone scaffold and other fields. Tr...Read more -

How to adjust injection molding process parameters?

The temperature Temperature measurement and control are very important in injection molding. Although these measurements are relatively simple, most injection molding machines do not have sufficient temperature points or wiring. In most injection machines, the temperature is sensed by a thermoc...Read more -

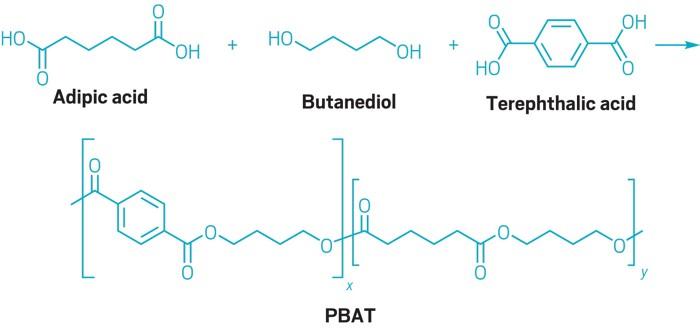

How to improve PLA material toughness

enterprises have expanded production, orders soared at the same time also caused the supply of raw materials, especially PBAT, PBS and other degradable membrane bag materials in just 4 months, the price soared. Therefore, the PLA material with relatively stable price has attracted attention. Po...Read more -

PBAT is closer to perfection than many polymers Ⅰ

Perfect polymers — polymers that balance physical properties and environmental effects — don’t exist, but polybutylene terephthalate (PBAT) is closer to perfection than many. After decades of failing to stop their products ending up in landfills and oceans, synthetic polymer mak...Read more