News

-

Application of Engineering Plastic PBT in Electronic and Electrical Industry

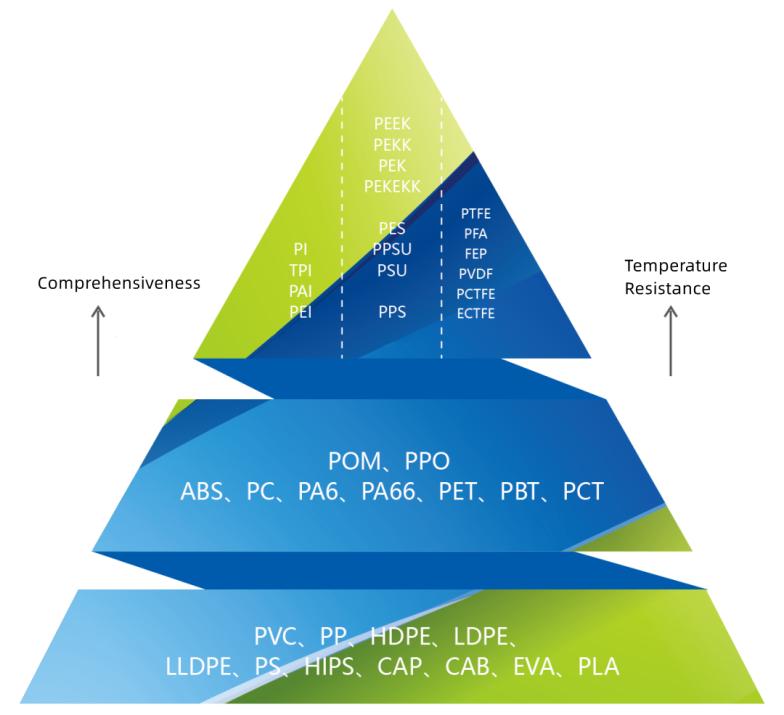

Polybutylene terephthalate(PBT). At present, more than 80% of the world’s PBT are modified after use, PBT modified engineering plastics with its excellent physical, mechanical and electrical characteristics in the electrical and electronic field is increasingly widely used. Modified PBT mat...Read more -

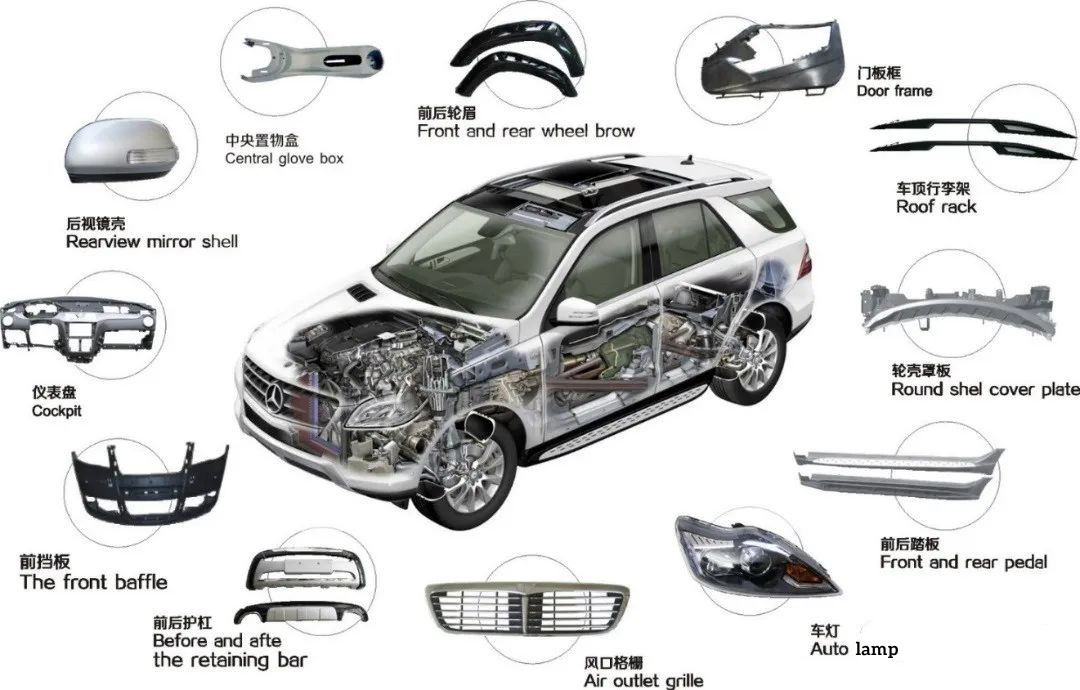

Engineering Plastics Used in The New Energy Vehicle Industry

The use of engineering plastics for new energy vehicles combined with automotive products needs to meet the following performance requirements: 1. Chemical corrosion resistance, oil resistance, high and low temperature resistance; 2. Excellent mechanical properties, high fluidity, excellent proce...Read more -

Properties and Applications of SIKO’s PBT Materials

PBT engineering plastics, (polybutylene terephthalate), has excellent comprehensive performance, relatively low price, and has good molding processing. In electronics, electrical appliances, mechanical equipment, automotive and precision instruments and other fields, it has been widely used. Char...Read more -

Applications and Advantages of Light Diffusion PC in Various Fields

Light diffusion PC, also known as polycarbonate light-diffusing plastic, is a kind of light-transmitting opaque polymerized by a special process with transparent PC (polycarbonate) plastic as the base material, adding a certain proportion of light-diffusing agent and other additives. of light dif...Read more -

Applications of PMMA in Automotive Field

Acrylic is polymethyl methacrylate, abbreviated as PMMA, is a kind of polymer polymer made from methyl methacrylate polymerization, also known as organic glass, with high transparency, high weather resistance, high hardness, easy processing molding and other advantages, is often used as a substit...Read more -

Application and Development Direction of Plastic Materials for New Energy Vehicles

At present, under the global development keynote of emphasizing “double carbon” strategy, saving, green and recycling have become the development trend of new automotive materials and new technologies, and lightweight, green materials and recycling have become the main development dir...Read more -

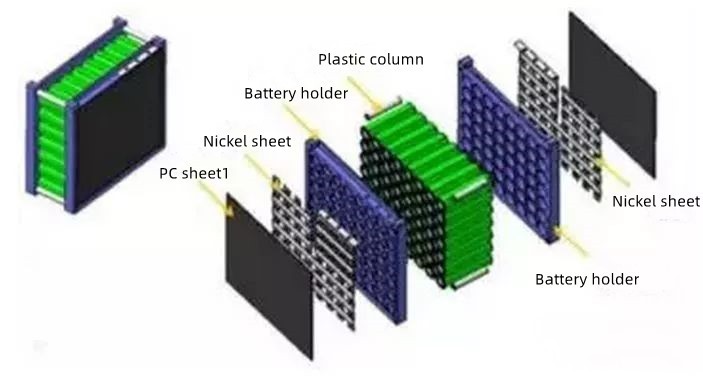

PPO’s Advantages in New Energy Vehicles

Compared with traditional cars, new energy vehicles, on the one hand, have a stronger demand for lightweight, on the other hand, there are more parts related to electricity, such as connectors, charging devices and power batteries, so they have higher requirements for high temperature and high pr...Read more -

Application of PPO, PC, PA in PV Junction Box

The photovoltaic junction box is a connector between the solar cell array composed of solar cell modules and the solar charge control device. It is a cross-disciplinary comprehensive design that combines electrical design, mechanical design and material science. 1. Requirements for photovoltaic ...Read more -

Potential Stock –PPO and Its Alloy Modified Materials

High-performance engineering plastics–PPO polyphenylene ether material. Excellent heat resistance, electrical properties, high strength and creep resistance and so on, endow PPO materials with application advantages in automotive, electronic appliances, 5G and other fields. Due to the high ...Read more -

Introduction of SIKO’s PPS Material

Introduction: Application: PPS is a kind of special engineering plastics with excellent comprehensive performance. PPS has excellent high temperature resistance, corrosion re...Read more -

Advantages Comparison of Special Plastics PPS and PEEK

In recent years, the application of special engineering plastics has gradually extended from the previous military and aerospace fields to more and more civilian fields, such as automobiles, equipment manufacturing, and high-end consumer goods. Among them, polyphenylene sulfide (PPS) and polyethe...Read more -

How to Achieve High Performance Polyamide Metal Replacement

As a leading global manufacturer of high-performance polyamides, SIKOPOLYMERS stands out from the industry with a wide range of materials, excellent rigidity and strength, and reliable high temperature resistance.。 Over the years, we have been committed to providing customers with cost-effective...Read more