News

-

Application of PPS in Pipe Fittings

First, the characteristics: 1、High strength, high toughness, high creep resistance, high torque: applicable to pipe fittings, joints, valve bodies, etc. with some internal threads for support and protection. 2、High temperature resistance, hydrolysis resistance, UV resistance: medical equipment ...Read more -

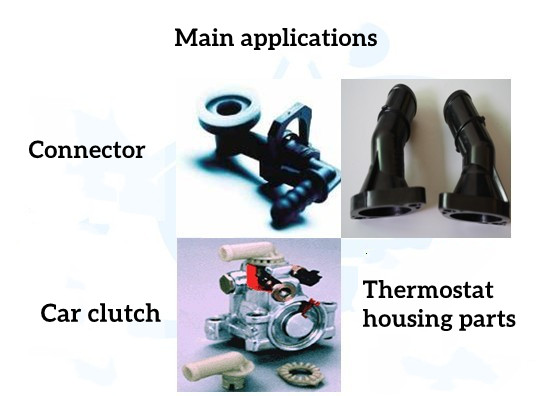

High Temperature Nylon PPA’s Characteristics and Main Applications

PPA material performance characteristics 1, PPA is a high temperature resistant material, with melt point between 310-325°C and a heat distortion temperature (HDT) between 280-290°C. 2, PPA has excellent oil resistance and excellent resistance to various oils such as fuel oil and lubricating oil,...Read more -

Why High Temperature Nylon is Loved To Be Used in Car Engine Peripheral Parts?

Due to the plasticization of electronic, motor parts, and automotive parts, higher requirements are placed on nylon performance and high temperature resistance. This opened the prelude to the research and development and application of high-temperature nylon. High-flow glass fiber reinforced high...Read more -

The Main Application Areas of High Temperature Nylon

High temperature nylon has been developed and applied more and more downstream in recent years because of its excellent performance, and the market demand has continued to rise. It has been widely used in electronic appliances, automotive manufacturing, LED and other fields. 1. Electronic and ele...Read more -

Application of High-performance Polymer-PPS in The Automotive Field

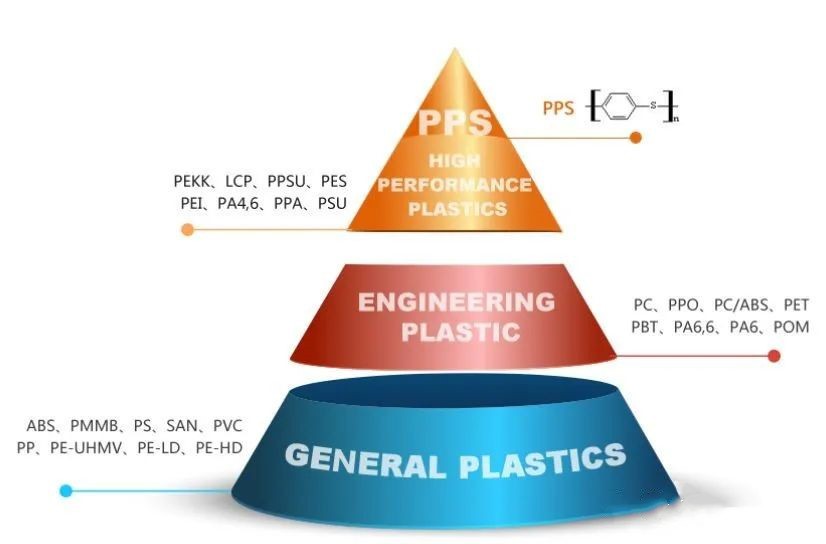

Polyphenylene sulfide(PPS), with a symmetrical rigid backbone, is a partially crystalline polymer consisting of repeating para-substituted benzene rings and sulfur atoms. PPS is a special engineering plastic with high performance and a high melting point of up to 280 ℃, ...Read more -

Applications of Nylon Material in Automotive Fuel System Parts

The automotive fuel system is composed of a fuel storage system, a fuel injection system, and a fuel supply pipeline system. Since the beginning of using plastic to produce fuel system components, this has become the mainstream way. Due to the light weight of the plastic, it can meet the requirem...Read more -

Main Applications of PEEK Engineering Plastics

PEEK is a high-performance organic thermoplastic polymer with excellent mechanical properties, high temperature properties, mechanical strength and excellent chemical resistance. It is an all-round special engineering plastic suitable for various additive manufacturing technologies. In recent yea...Read more -

Applications of Nylon Material in Automobile Engine

Parts in automobiles are an important and rapidly developing field of nylon product application. Nylon has very good comprehensive properties, easy to form and low density, so it has been well used in mold development and assembly. The parts inside the engine area of the car need to withstand the...Read more -

Why PPS Excellent On Metal Replacement?

Some people thought that replacing metal with PPS plastic would reduce product quality. Actually, the use of PPS metal replacement can improve product quality in many occasions. PPS material has the advantages of high temperature resistance, high strength,high modulus, high heat resistance, wear...Read more -

SIKO’s high performance material successful used in Electronic and Electrical Engineering and Machinery industry

High temperature nylon refers to the nylon material that can be used in an environment above 150℃ for a long time. The melting point is generally 290℃~320℃, and the thermal deformation temperature of glass fiber modification is greater than 290℃. It also maintains excell...Read more -

Polyphenylene sulfide (PPS) material widely used in Electronic and Electrical Engineering

In recent years, the rapid development of electronic and electrical industry, its products are more and more powerful, at the same time, the demand for multifunctional materials is also increasingly vigorous. PPS electrical properties are very outstanding, compared with ...Read more -

SIKO’s high performance PPA material successful used in automotive field

SIKO’s high performance PPA composite material are widely used to manufacture high precision, high temperature resistant and high strength products. Especially for automotive engine peripheral products, which need to cope with increasingly stringent aging requirements, h...Read more