In recent years, the rapid development of electronic and electrical industry, its products are more and more powerful, at the same time, the demand for multifunctional materials is also increasingly vigorous. PPS electrical properties are very outstanding, compared with other engineering plastics, its dielectric constant and dielectric loss Angle tangent are relatively low, and in a large frequency, temperature and temperature range of little change, which makes it widely used in electronic and electrical fields.

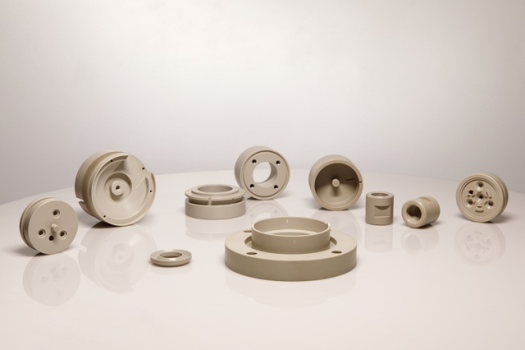

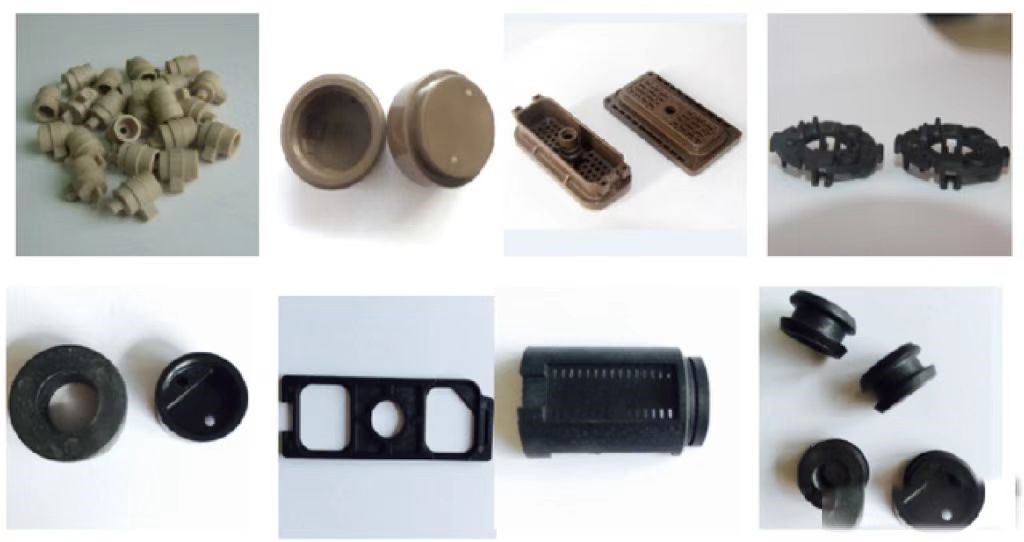

Electronic and electrical is the most common and earliest industry to use polyphenylene sulfide. It is generally used for various connectors, coil tubes, solid state relays, magnetic sensor induction heads, connectors, sockets, coil skeletons, trimmer capacitors, and fuse bases. Wait. Because of its good dimensional stability, polyphenylene sulfide is also often used to make various precision instrument parts, such as parts for cameras, tachometers, gears, electronic watches, optical read heads, microwave ovens, copiers, computers, CDs, etc. PPS also has good performance in electronic packaging materials and mechanical sealing materials, and can replace epoxy resins as packaging materials or special papers for the electronic industry in the special semiconductor manufacturing process.

Its main attributes and characteristics are as follows:

1. Heat resistance for continuous use at 200°C or higher

2. Has strong chemical resistance, heat resistance, vibration resistance and impact resistance

3. Excellent strength, plasticity and rigidity in a wide temperature range

4. Excellent dimensional stability under most environmental conditions

5. Advanced electrical performance under high temperature, high humidity and high frequency

Due to these special properties and characteristics of PPS, it shines in the field of electronic appliances.

Post time: 23-07-22