Polyphenylene sulfide (PPS) is a kind of thermoplastic special engineering plastic with good comprehensive properties. Its outstanding characteristics are high temperature resistance, corrosion resistance and superior mechanical properties.

PPS is widely used in automobile, electrical and electronic, machinery industry, petrochemical industry, pharmaceutical industry, light industry, military industry, aerospace, 5G communication and other fields, is one of the most widely used special engineering plastics.

With the advent of the 5G era, PPS has also expanded into this emerging field.

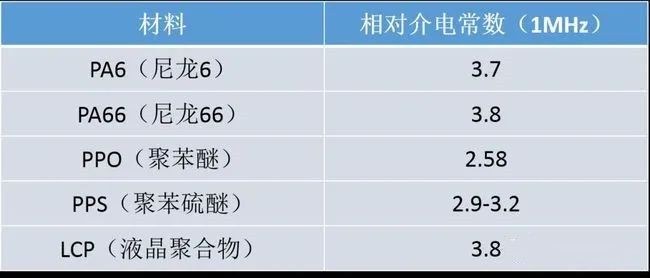

5G is the fifth generation of mobile communication technology, the transmission speed is more than 100 times that of 4G, so 5G materials have high requirements on dielectric constant. Generally, the permittivity of the resin material is only required to be below 3.7 for 4G products, while the permittivity of the resin composite material is generally required to be between 2.8 and 3.2 for 5G products.

Comparison of dielectric constants

The characteristics of PPS

1. Thermal properties

PPS has outstanding heat resistance, especially under high humidity and high stress conditions. PPS electrical insulation heat resistance grade reaches F (YAEBFH grade, heat resistance grade increases in turn). PPS film has the highest flame retardant (self-extinguishing) when there is no additives at all. PPS film over 25mm is identified as UL94 V0 grade material.

2. Mechanical characteristics

The tensile properties and processing properties of PPS film are similar to those of PET, and PPS film can still maintain high strength and toughness at low temperature of -196℃, which can be used as insulation material related to superconductivity.

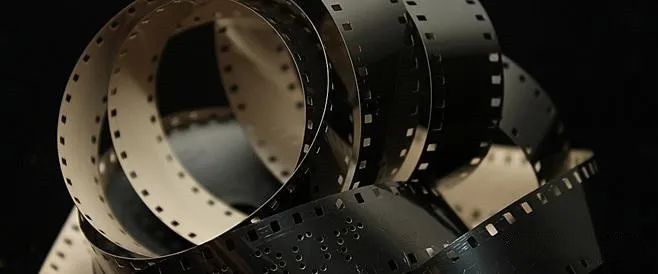

Moreover, the long-term creep and moisture absorption of PPS is much lower than that of PET film, especially the effect of moisture on PPS film is very small, so the dimensional stability is very good, which can replace PET as magnetic recording medium, photography and other image-related base film materials.

3. Chemical properties

PPS resistant to most organic solvents, in addition to concentrated sulfuric acid, concentrated nitric acid impregnation, only in 2-chlornaphthalene, diphenyl ether and other special solvents above 200℃ only began to dissolve, its resistance is second only to plastic king PTFE.

4. Electrical

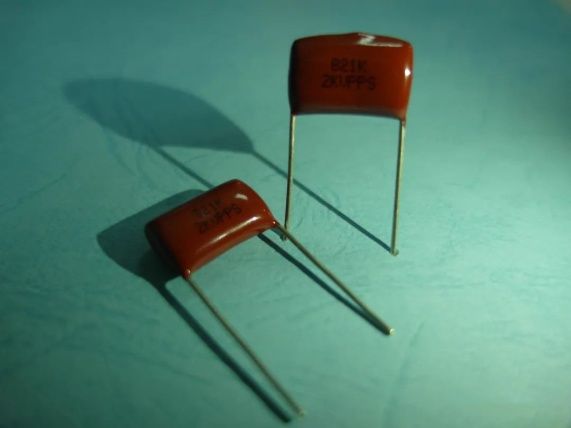

PPS has high frequency electrical characteristics, its dielectric constant is extremely stable in a wide range of temperature and frequency, and its dielectric loss Angle tangent is small enough to rival polypropylene. As capacitor dielectric, its capacitance has little dependence on temperature and frequency, so low loss capacitor can be obtained.

PPS capacitor

5. Other performance

The surface tension of PPS film is slightly lower than that of PET film, but it is also suitable for coating processing. In cases where adhesive is used with other film laminates, the surface should be corona treated to increase the surface tension to 58d/cm.

The surface roughness and friction coefficient of PPS film can be adjusted according to the purpose just like PET. PPS membrane is one of the few organic membranes that can be used in the periphery of nuclear reactor and fusion furnace because of its high durability against r ray and neutron ray.

PPS film capacitance

The application of PPS in 5G field

1. FPC (flexible circuit board) is a must-have in 5G industry forever.

Flexible circuit (FPC) is the United States in the 1970s for the development of space rocket research and development, through the flexible thin plastic sheet, embedded circuit design, so that a large number of precision components in a narrow and limited space, so as to form a flexible circuit.

Liquid crystal polymer (LCP) film is widely used in the market. However, the high cost and processing characteristics of LCP are still a problem, so the emergence of a new material is the urgent need of the market.

Toray has effectively targeted the market and demand with its cutting-edge technology to manufacture biaxial stretched polyphenylene sulfide (PPS) film Torelina®. It has the same or even better dielectric properties than LCP film.

Torelina ® application

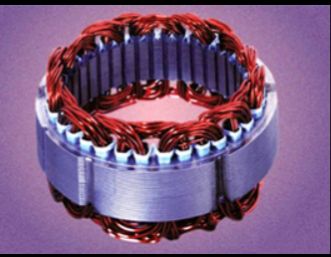

Electrical insulation material (motor/transformer/wire)

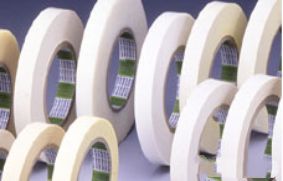

Electronic Components (lithium batteries/capacitors)

Engineering thin film (electrical material)

Advantages in FPC

Materials with low dielectric loss in high frequency range.

Stable transmission loss under high temperature and humidity conditions.

In the automobile, electrical industry has been mass production.

Low water absorption & hydrolysis resistance.

It is the best alternative to LCP & MPI(Modified polyimide).

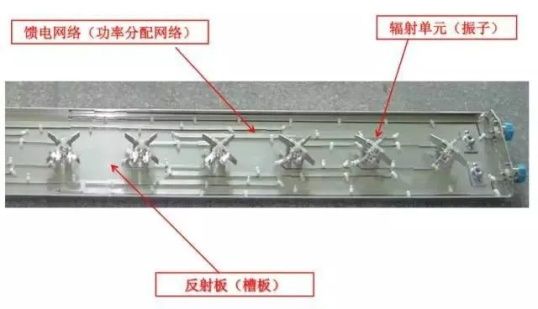

2. Plastic antenna oscillator

The so-called antenna oscillator is simply a piece of metal conductor that transmits and receives high-frequency oscillating signals. This is the 4G antenna, and the 5G antenna will be much smaller.

Traditional antenna vibrator used material is metal or PC board, after 5 g era, as demand a higher quality of communication, the number of vibrator would increase greatly, if still use metal materials, can let antenna become extremely heavy, cost is very expensive, so in 5 g antenna oscillator design is essentially the choice of the high temperature engineering plastics.

Plastic antenna oscillator

The antenna oscillator can be modified with 40% glass fiber reinforced PPS, which has high production efficiency, significantly lower weight and cost than LCP and PCB oscillator, and better comprehensive conditions. It is expected to become mainstream material.

Post time: 20-10-22