Special engineering plastics refer to engineering plastics with high comprehensive properties and long-term service temperature above 150℃. Generally both high temperature resistance, radiation resistance, hydrolysis resistance, weather resistance, corrosion resistance, natural flame retardant, low thermal expansion rate, fatigue resistance and other advantages. There are many kinds of special engineering plastics, including polyliquid crystal polymer (LCP), polyether ether ketone (PEEK), polyimide (PI), phenyl sulfide (PPS), polysulfone (PSF), polyaromatic ester (PAR), fluoropolymers (PTFE, PVDF, PCTFE, PFA), etc.

From the perspective of history and current situation, the European and American countries from the advent of polyimide in the 1960s and the advent of polyether ether ketone in the early 1980s, up to now has formed more than 10 kinds of special engineering plastics industrialization. China’s special engineering plastics started in the middle and late 1990s. At present, the industry is in the initial stage of development, but the development speed is fast. Several common special engineering plastics are taken as examples.

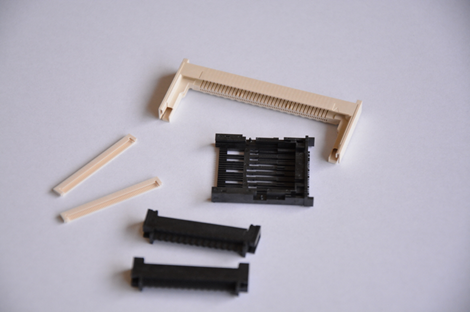

Liquid crystal polymer (LCP) is a kind of aromatic polyester material containing a large number of rigid benzene ring structure on the main chain, which will change into liquid crystal form under a certain heating state, and has excellent comprehensive properties. At present, the global capacity of liquid crystal polymer is about 80,000 tons/year, and the United States and Japan account for about 80% of the global total capacity. China’s LCP industry started late, with the current total production capacity of about 20,000 tons/year. The main manufacturers include Shenzhen Water New Materials, Zhuhai Vantone, Shanghai Puliter, Ningbo Jujia, Jiangmen Dezotye, etc. It is expected that the total consumption of LCP will maintain a growth rate of more than 6% and exceed 40,000 tons in 2025, driven by the demand of electronic and electrical appliances and automobile sectors.

Polyether ether ketone (PEEK) is a semi-crystalline, thermoplastic aromatic polymer material. At present, there are three types of polyether ether ketones on the market: pure resin, glass fiber modified, carbon fiber modified. At present, Wiggs is the world’s largest producer of polyether ketone, with a production capacity of about 7000 tons/year, accounting for about 60% of the world’s total capacity. The technology development of POLYEther ether ketone in China started late, and the production capacity is mainly concentrated in Zhongyan, Zhejiang Pengfu Long and Jida Te Plastics, accounting for 80% of the total production capacity in China. It is expected that in the next five years, the demand for PEEK in China will maintain a growth rate of 15% ~ 20% and reach 3000 tons in 2025.

Polyimide (PI) is an aromatic heterocyclic polymer compound containing imide ring in the main chain. Seventy percent of PI’s global production is in the United States, Japan, South Korea and other countries. PI film is also known as “gold film” for its excellent performance. At present, there are about 70 polyimide film manufacturers in China, with a production capacity of about 100 tons. They are mainly used in the low-end market, while the independent research and development level of high-end products is not high, and they are mainly imported.

PPS is one of the most important and common kinds of polyaryl sulfide resins. PPS has excellent thermal performance, electrical performance, chemical resistance, radiation resistance, flame retardant and other properties. PPS is a thermoplastic special engineering plastic with excellent comprehensive performance and high cost performance. PPS is often used as structural polymer material. It is widely used in automobile, electronic and electrical, chemical, machinery, aerospace, nuclear industry, food and drug industry and other fields.

From the application field, special engineering plastics in addition to the application in the electronic, automotive, aerospace, precision instruments, and other traditional areas, with 5 g communications, new energy vehicles, high pressure connector, consumer electronics, semiconductor, healthcare, energy and other industries, with the rapid development of the application of special engineering plastics is also expanding, amount and type of application are rising.

From the mid-stream modification and processing, special engineering plastics often need to be modified by glass/carbon fiber reinforcement, toughening, mineral filling, antistatic, lubrication, dyeing, wear resistance, blending alloy, etc., to further enhance their application value. Its processing and post-processing methods include blending modification, injection molding, extrusion film, impregnation composite, bar profiles, mechanical processing, which will use a variety of additives, processing equipment, etc..

Post time: 27-05-22