Polyether ether ketone resin (polyetheretherketone, referred to as PEEK resin) is a kind of high temperature thermoplastic with high glass transition temperature (143C) and melting point (334C). The load thermal deformation temperature is as high as 316C (30% glass fiber or carbon fiber reinforced). It can be used for a long time at 250C. Compared with other high temperature resistant plastics such as pi, pps, ptfe, ppo, etc., the upper limit of service temperature exceeds about 50 ℃.

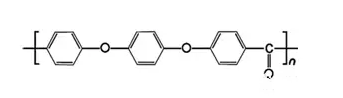

The structural formula is as follows:

Properties

PEEK resin not only has better heat resistance than other high temperature resistant plastics, but also has high strength, high modulus, high fracture toughness and good size invariance.

PEEK resin can maintain high strength at high temperature, and its zigzag strength is up to 24mpa at 200C, and its flexural strength and compressive strength are still 12~13mpa at 250C.

PEEK resin has high rigidity, good size invariance and small linear expansion coefficient, which is very close to that of aluminum.

It has excellent chemical resistance. Among the chemicals, only concentrated sulfuric acid can melt or crush it. Its corrosion resistance is similar to that of nickel steel. At the same time, it has flame retardancy and releases less smoke and toxic gases under the premise of flame. Strong radiation resistance.

PEEK resin has good toughness and good decay resistance to alternating stress, which is the most outstanding of all plastics, which is comparable to alloy materials.

PEEK resin has outstanding tribological characteristics, excellent sliding wear resistance and fretting wear resistance, especially high wear resistance and low friction coefficient at 250C.

PEEK resin has the advantages of easy extrusion and injection molding, excellent processing function and high molding efficiency.

PEEK also has excellent functions such as good self-lubricity, easy processing, constant insulation, hydrolysis resistance and so on.

Applications

Electronic and electrical appliances

In the field of electronics and electrical appliances, PEEK resin has good electrical function and is a good electrical insulator. It can still maintain excellent electrical insulation under the harsh working conditions such as high temperature, high voltage and high humidity. Therefore, the field of electronics and electrical appliances has gradually become the second largest application category of PEEK resin.

In the semiconductor industry, PEEK resin is often used to manufacture wafer carriers, electronic insulating diaphragms and all kinds of connecting devices, as well as wafercarrier insulating films, connectors, printed circuit boards, high temperature connectors and so on.

In addition, PEEK resin can also be used in ultra-pure water transportation and storage equipment, such as pipes, valves, pumps and accumulators.

At present, PEEK resin is also being used in the production of integrated

Medical treatment

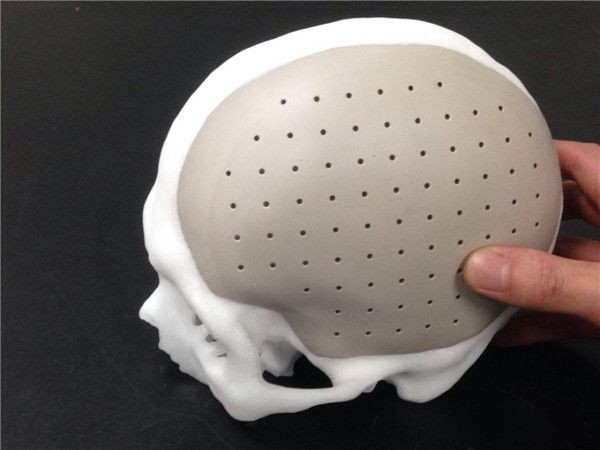

In the medical field, in addition to the surgical and dental equipment that requires high sterilization and several times of use, and the construction of some compact medical instruments, the most important use of PEEK resin is artificial bone that can replace metal construction. The artificial bone made of PEEK resin not only has the advantages of light weight, non-toxicity and strong corrosion resistance, but also the closest material to human bone in plastic, which can be connected with the body organically. therefore, using PEEK resin instead of metal to make human bone is a primary use in medical field, which has far-reaching significance and value.

Machinery industry

In the mechanical industry, PEEK resin is often used to build tightening machine valve plates, piston rings, seals and various chemical pump bodies and valve components. The impeller of swirl pump is built with this resin instead of stainless steel. in addition, PEEK resin meets the specification requirements of pipe group workpiece materials, and all kinds of adhesives can still be used for bonding at high temperature, so modern connectors will be another potential market.

Automobile

PEEK polymeric materials can successfully replace metals, traditional composite materials and other plastics because of their unusually strong, chemical inertia and flame retardant properties, and are easy to be processed into parts with very small tolerances. PEEK has the advantages of light specific gravity, anti-corrosion and temperature resistance.

PEEK polymeric materials have been officially approved by a number of aircraft manufacturers, but also meet the requirements of the supply of military standard products, PEEK resin can make a variety of aircraft parts-the application in the aerospace field has expanded rapidly.

Aerospace

In aerospace, PEEK resin can replace aluminum and other metal materials to make all kinds of aircraft parts, control its excellent flame retardant function, and can be used to make aircraft internal parts to land the aircraft in case of fire risk.

Fuel source power

In the aspect of fuel source power, PEEK resin is resistant to high temperature, not easy to hydrolyze and resistant to radiation, so the wire and cable coil framework built with it has been successfully used in nuclear power plants.

Petroleum exploration.

In the petroleum exploration and exploitation industry, it can be used to make probes of special geometric dimensions touched by mining machinery.

Coating material

In the aspect of coating, the metal with good insulation, strong corrosion resistance, heat resistance and water resistance can be obtained by covering the powder coating of PEEK resin on metal.

PEEK powder coating products are widely used in chemical anti-corrosion, household appliances, electronics, machinery and other fields.

In addition, PEEK resin can also be used to manufacture packed columns and connecting ultra-fine tubes for liquid chromatographic analysis instruments.

Post time: 16-02-23