OEM Factory for Pa 66 Gf 35 - High rigidity PPO- GF, FR reinforced with glass fiber for water pump – Siko

OEM Factory for Pa 66 Gf 35 - High rigidity PPO- GF, FR reinforced with glass fiber for water pump – Siko Detail:

PPO blends are used for structural parts, electronics, household and automotive items that depend on high heat resistance, dimensional stability and accuracy. They are also used in medicine for sterilizable instruments made of plastic.[3] The PPE blends are characterized by hot water resistance with low water absorption, high impact strength, halogen-free fire protection and low density.

This plastic is processed by injection molding or extrusion; depending on the type, the processing temperature is 260-300 °C. The surface can be printed, hot-stamped, painted or metalized. Welds are possible by means of heating element, friction or ultrasonic welding. It can be glued with halogenated solvents or various adhesives.

This plastic is also used to produce air separation membranes for generating nitrogen.[4] The PPO is spun into a hollow fiber membrane with a porous support layer and a very thin outer skin. The permeation of oxygen occurs from inside to out across the thin outer skin with an extremely high flux. Due to the manufacturing process, the fiber has excellent dimensional stability and strength. Unlike hollow fiber membranes made from polysulfide, the aging process of the fiber is relatively quick so that air separation performance remains stable throughout the life of the membrane. PPO makes the air separation performance suitable for low temperature (35-70 °F; 2-21 °C) applications where polysulfide membranes require heated air to increase permeation.

PPO Features

PPO has the smallest density and is non-toxic in compliance with FDA standards among the five major engineering plastics.

Outstanding heat resistance, higher than PC in amorphous materials

The electrical properties of PPO are the best in general engineering plastics, and temperature, humidity and frequency have little effect on their electrical properties.

Low PPO/PS shrinkage and good dimensional stability

PPO and PPO/PS series alloys have the best hot water resistance in general engineering plastics, the lowest water absorption, and small dimensional changes when used in water.

PPO/PA series alloys have good toughness, high strength, solvent resistance and spray ability

Flame-retardant MPPO generally uses phosphorus-nitrogen flame retardant, which has the characteristics of halogen-free flame retardant and meets the development direction of green materials.

PPO Main Application Field

The products on the market are improved products with excellent comprehensive properties. Widely used in electrical and electronic, automotive industry, machinery and chemical industries.

| Field | Application Cases |

| Auto Parts | Well pumps, circulation pump, underwater pump bowl and impellers, coffee pot cover, shower, steam hot water pipe, valves. |

| Electrical & Electronic parts | Connectors, coil bobbins, LED boards, switches, relays bases, large displays, AC transformer adapters, IF transformer bobbins, sockets, engine components, etc. |

| Industrial parts and consumer products | Dashboard, battery pack, switchboard, radiator grille, steering column housing, control box, anti-frost device trim, fuse box, relay housing assembly, headlight reflector. Door panel, chassis, wheel cover, choke Board, fender, fender, rear view mirror, trunk lid, etc. |

SIKO PPO Grades And Description

| Field | Filler(%) | FR(UL-94) | Description |

| SPE40F-T80 | None | V0 | HDT 80℃-120℃, HighFlowability, Halogen FreeFalme Retardant V0 |

| SPE40G10/G20/G30 | 10%-30% | HB | PPO+10%,20%,30%GF,Good dimension stability, resistant to Hydrolysis, |

| SPE40G10/G20/G30F-V1 | 10%-30% | V1 | PPO+10%, 20%, 30%GF, Good dimension stability, resistant to Hydrolysis, Halogen free FR V1. |

| SPE4090 | None | HB/V0 | Good flowability,Chemical resistance, high strength. |

| SPE4090G10/G20/G30 | 10%-30% | HB | PPO+10%,20%,30% GF,good rigidity and chemical resistance. |

Grade Equivalent List

| Material | Specification | SIKO grade | Equivalent to Typical brand & grade |

| PPO | PPO Unfilled FR V0 | SPE40F | SABIC NORYL PX9406 |

| PPO+10%GF, HB | SPE40G10 | SABIC NORYL GFN1 | |

| PPO+20%GF, HB | SPE40G20 | SABIC NORYL GFN2 | |

| PPO+30%GF, HB | SPE40G30 | SABIC NORYL GFN3 | |

| PPO+20%GF, FR V1 | SPE40G20F | SABIC NORYL SE1GFN2 | |

| PPO+30%GF, FR V1 | SPE40G30F | SABIC NORYL SE1GFN3 | |

| PPO+PA66 Alloy+30%GF | SPE1090G30 | SABIC NORYL SE1GFN3 |

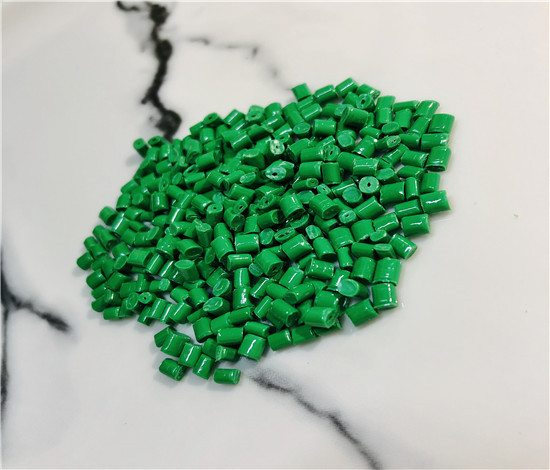

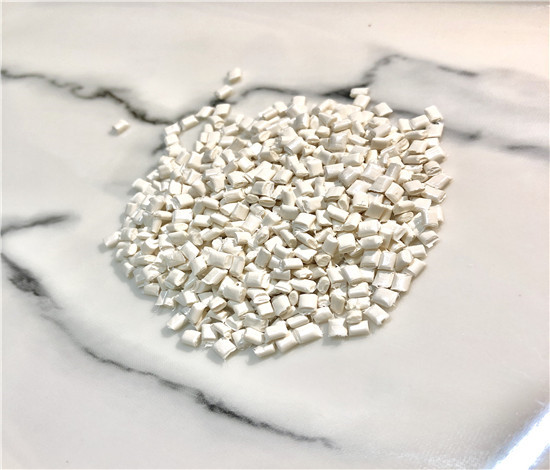

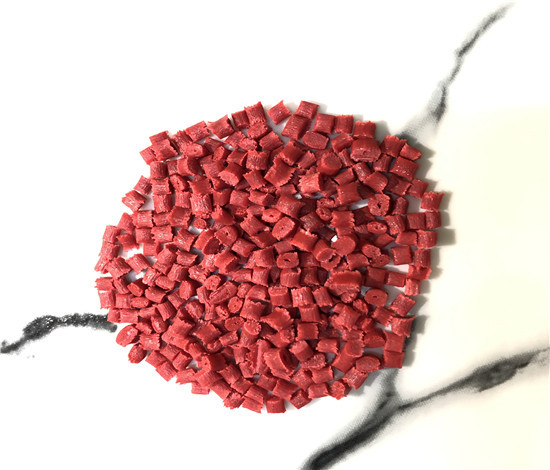

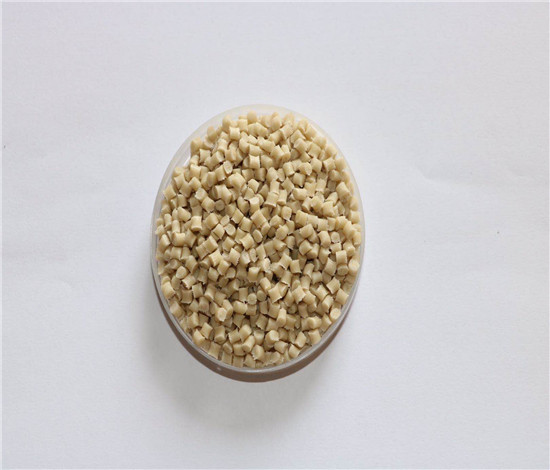

Product detail pictures:

Related Product Guide:

"Quality initially, Honesty as base, Sincere company and mutual profit" is our idea, in order to create repeatedly and pursue the excellence for OEM Factory for Pa 66 Gf 35 - High rigidity PPO- GF, FR reinforced with glass fiber for water pump – Siko , The product will supply to all over the world, such as: Turkey, New York, UK, We've been consistently broadening the market within Romania in addition to preparation punching in extra premium quality merchandise connected with printer on t shirt so that you can Romania. Most people firmly believe we've the whole capacity to provide you happy solutions.

Problems can be quickly and effectively resolved, it is worth to be trust and working together.