One of Hottest for Ppo Gf20 - Good factory price PA6-GF, FR flame retardant for auto parts – Siko

One of Hottest for Ppo Gf20 - Good factory price PA6-GF, FR flame retardant for auto parts – Siko Detail:

Nylon 6 fibers are tough, possessing high tensile strength, elasticity and luster. They are wrinkle proof and highly resistant to abrasion and chemicals such as acids and alkalis. The fibers can absorb up to 2.4% of water, although this lowers tensile strength. The glass transition temperature of Nylon 6 is 47 °C.

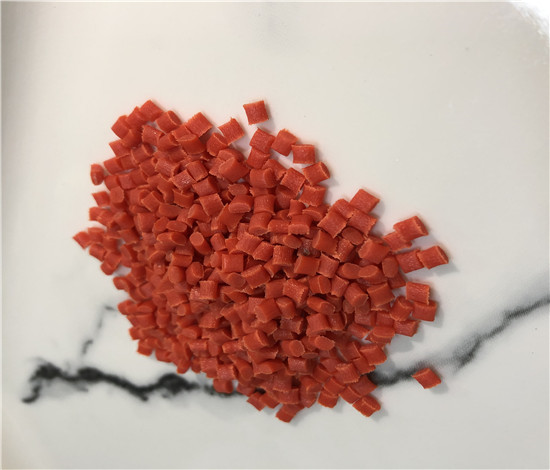

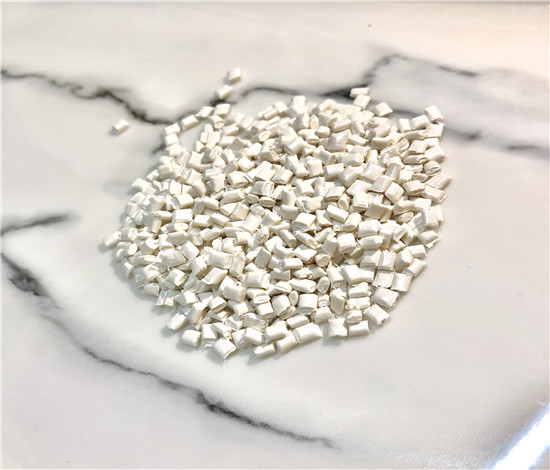

As a synthetic fiber, Nylon 6 is generally white but can be dyed in a solution bath prior to production for different color results. Its tenacity is 6–8.5 gf/D with a density of 1.14 g/cm3. Its melting point is at 215 °C and can protect heat up to 150 °C on average.

At present, polyamide 6 is the most significant construction material used in many industries, for instances in automotive industry, aircraft industry, electronic and electro technical industry, clothing industry and medicine. Annual demand for polyamides in Europe amounts to a million tones. They are produced by all leading chemical companies.

It is a semi crystalline polyamide. Unlike most other nylons, nylon 6 is not a condensation polymer, but instead is formed by ring-opening polymerization; this makes it a special case in the comparison between condensation and addition polymers. Its competition with nylon 6,6 and the example it set have also shaped the economics of the synthetic fiber industry.

PA6 Features

High mechanical strength, good toughness, high tensile and compressive strength.

Corrosion resistant, very resistant to alkali and most salt liquids, also resistant to weak acids, engine oil, gasoline, aromatic hydrocarbon-resistant compounds and general solvents.

Self-extinguishing, non-toxic, odorless, weather resistant, inert to bio-erosion, good antibacterial and anti-mildew ability.

Excellent electrical properties, the electrical insulation is good, the volume resistance very high, and the breakdown voltage is high. In the dry environment, it can be used as a power frequency insulation material, and has good electrical insulation even in a high humidity environment.

The parts are light in weight, easy to matching color and molding. It can flow quickly due to its low melt viscosity.

PA6 Main Application Field

| Field | Application cases |

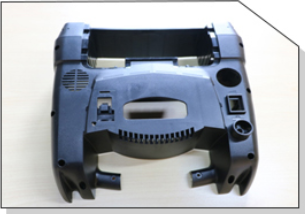

| Auto parts | Radiator box and blade, tank cover, door handle, intake grille |

| Electrical & Electronic parts | Coil bobbin, electronic connector, electrical original, low voltage electrical housing, terminal |

| Industrial parts | Bearings, round gears, various rollers, oil resistant gaskets, oil resistant containers, bearing cages |

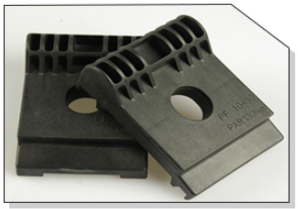

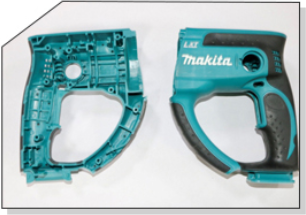

| Railway fasten parts, Power tools | Rail insulator, angle guide, pad, power tools parts |

SPLA-3D Grades And Description

| SIKO Grade No. | Filler(%) | FR(UL-94) | Description |

| SP80G10-50 | 10%-50% | HB | PA6+10%, 20%, 25%, 30%,50%GF, Glassfiber reinforced grade |

| SP80GM10-50 | 10%-50% | HB | PA6+10%, 20%, 25%, 30%,50%GF, Glassfiber reinforced grade |

| SP80G25/35-HS | 25%-35% | HB | PA6+25%-35%GF, heat resistance |

| SP80-ST | None | HB | PA6 unfilled, PA6+15%, 20%, 30%GF,Super Toughness grade, High impact, Dimension stability, low temperature resistance. |

| SP80G20/30-ST | 20%-30% | HB | |

| SP80F | None | V0 | Flame retardant PA6 |

| SP80G15-30F | 15%-30% | V0 | PA6+15%, 20%, 25%, 30%GF, and FR V0 |

Grade Equivalent List

| Material | Specification | SIKO grade | Equivalent to Typical brand & grade |

| PA6 | PA6 +30%GF | SP80G30 | DSM K224-G6 |

| PA6 +30%GF, High impact modified | SP80G30ST | DSM K224-PG6 | |

| PA6 +30%GF, Heat stabilized | SP80G30HSL | DSM K224-HG6 | |

| PA6 +20%GF, FR V0 Halogen free | SP80G20F-GN | DSM K222-KGV4 | |

| PA6 +25% Mineral filler, FR V0 Halogen free | SP80M25-GN | DSM K222-KMV5 |

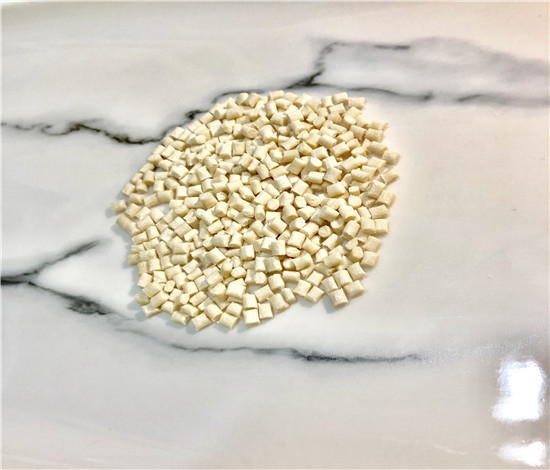

Product detail pictures:

Related Product Guide:

Our personnel are generally within the spirit of "continuous improvement and excellence", and using the excellent top quality goods, favorable rate and superior after-sales expert services, we try to win every customer's believe in for One of Hottest for Ppo Gf20 - Good factory price PA6-GF, FR flame retardant for auto parts – Siko , The product will supply to all over the world, such as: Johannesburg, Italy, Sudan, We firmly think that we have the full capability to give you contented merchandise. Wish to collect concerns within you and build a new long-term synergy romantic relationship. We all significantly promise:Csame excellent, better selling price; exact selling price, better quality.

The company has a good reputation in this industry, and finally it tured out that choose them is a good choice.